Some Key Benefits For Using Rapid Tooling for Product Development and Design

One prominent challenge that the product designer’s face isn’t having the ability to make their clients to know how the product may feel and look. The additive manufacturing or rapid tooling technology is gaining huge importance among engineering manufacturers and designers, since it offers the fast and the accurate way of realizing potential of any […]

Metal Fabrication for the Energy Industry

As environmental concerns for conventional energy sources continue to rise, renewable energy manufacturing is taking front row and playing a vital role in delivering clean energy for future use. Metal fabrication is one of the avenues for delivering infrastructure in the energy industry. As a metal fabrication company, Firstpart delivers a complete range of essential […]

Understanding Single-cavity, Multi-cavity, and Family Cavity Mold Concepts

The cost of making injection mold tooling is inarguably part of the biggest expense lines and fixed costs in mass plastic part production. So delicate is the injection mold tooling that a single error in its design will be reflected in all the copies of the part that will be made from the tool. More […]

Introduction to Geometric Dimensioning and Tolerances (Part 2)

In our last article on geometric dimensioning and tolerance, we discussed the basics of GD&T and the many benefits of using it for CNC design. Today, we continue by looking at the other half of GD&T. This concludes the introduction to GD&T, covering tolerancing guidelines and tolerancing symbols. GD&T Tolerancing Symbols […]

ISO 9001 Driven Manufacturing & Its Importance

The International organization for standardization, ISO, is the world’s largest and most versatile developer and regulator of standards and framework. ISO standards help to protect both companies and consumers, and may be seen as a panacea for consistency and reliability in brands, products and services. In manufacturing and production, quality control is vital to maintaining […]

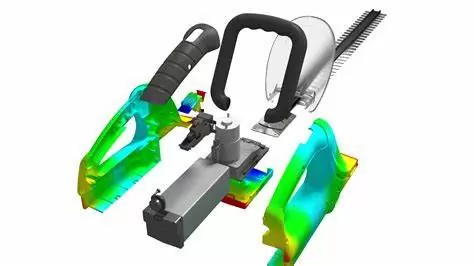

Improving Part Manufacturability Using Mold Filling Simulation

Design for manufacturability (DFM) is a critical part of different manucturing techniques. DFM basically refers to the set of guidelines that product designers should align with to reduce the chances of manufacturing failure in their part production. For injection molding, there are many components of DFM. One of such components is Mold filling simulation. What […]