Surface Finishing Options

- Nanoscale Coating Uniformity (±0.1μm)

- MIL-SPEC & ASTM Compliance

- Optimized 3D Surface Mapping

What is Surface Finishing?

Surface finishing is the umbrella term for the many processes used to modify the surface appearance and texture of a manufactured product, and convey the desired feel and look to the part. Generally, a part may be finished to improve appearance introduce customization, and convey specific characteristics (functionality).

The most common surface finishes are used to improve abrasion-resistance, increase oxide layers, improve hardness, conductivity, adherence, and corrosion-resistance. The texture of a part may also be modified to make it smoother, grittier, or engrave or etch details into its surface.

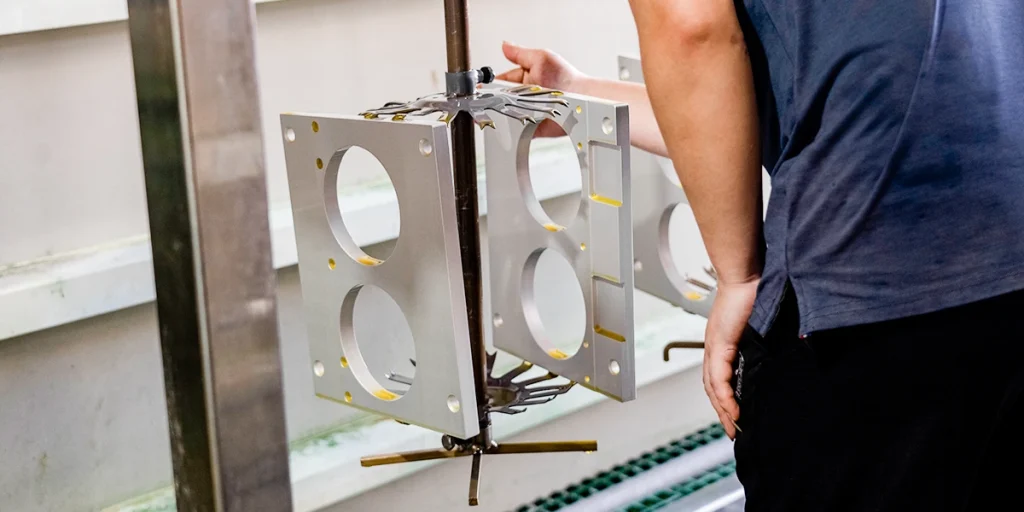

High-quality Design, Top-grade Finish

Achieve the perfect finish to complement your part design and appearance with First Part art Finishing Services. At First Part, we leverage advanced color matching, part texturing, and other functional techniques to deliver the perfect part with attention-arresting cosmetic details. Our finishing services is your best choice at making beautiful end parts that stand out from the crowd and make the best impression at first glance. From anodizing to plating, powder coating, texturing, and polishing, we guarantee an outcome that delivers finesse and superior aesthetics to your part. Click here to get started with a free quote!

Our Finishing Operations

Standard/As manufactured

The standard finish of any part is the basic cosmetic appearance of the part immediately it is manufactured. It refers to the state of the part when ejected, machined, printed, or cast. This finish will have visible tooling marks, resin, or powder remnants as applicable to the production method.

It is suitable for parts that will form a bigger machine’s inner components and will be situated in areas where they do not contribute to the overall cosmetic appearance of the piece.

| Category | Process | Key Detail | Price |

|---|---|---|---|

| Mechanical | Sandblasting | Matte/textured finish | $ |

| Polishing | Mirror-like surface | $$ | |

| Grinding | Precision flatness | $$$ | |

| Chemical | Anodizing | Corrosion-resistant layer | $$-$$$ |

| Passivation | Stainless steel protection | $ | |

| Chromating | Zinc/Aluminum coating | $$ | |

| Coatings | Powder Coating | Durable polymer layer | $$ |

| PVD Coating | Thin-film wear resistance | $$$$ | |

| CVD Coating | High-temp protection | $$$$ | |

| Electrochemical | Electroplating | Metal deposition (e.g., Ni) | $$-$$$ |

| Electropolishing | Smoothing via electrolysis | $$$ | |

| Thermal | Tempering | Stress relief for metals | $$ |

| Case Hardening | Surface hardness boost | $$$ | |

| Plastic-Specific | Laser Etching | Permanent markings | $$ |

| Vacuum Metallization | Reflective plastic surfaces | $$$ | |

| Other | Hydro Dipping | Camouflage patterns | $$-$$$ |

| Plasma Treatment | Adhesion enhancement | $$ |

Finishing Applications

First Part Finishing Services can be applied for:

- Injection-molded Parts

- CNC Machined Parts

- Rapid Tooling

- Over-molded parts

- Insert-molded parts

- 3D-printed Parts

- Metal Die-casted Parts

- Sheet Metal Fabrications

- Extruded Parts

- Urethane/Vacuum-casted parts