CNC Machining Service

- 100+ Materials & Finishing For Choosen

- Machined in as fast as 1 day

- High Quality & Competitive price

Certifications: IATF 16949:2016, ISO 9001:2015

Flexible MOQ

from 1 to 10,000 as per your needs.

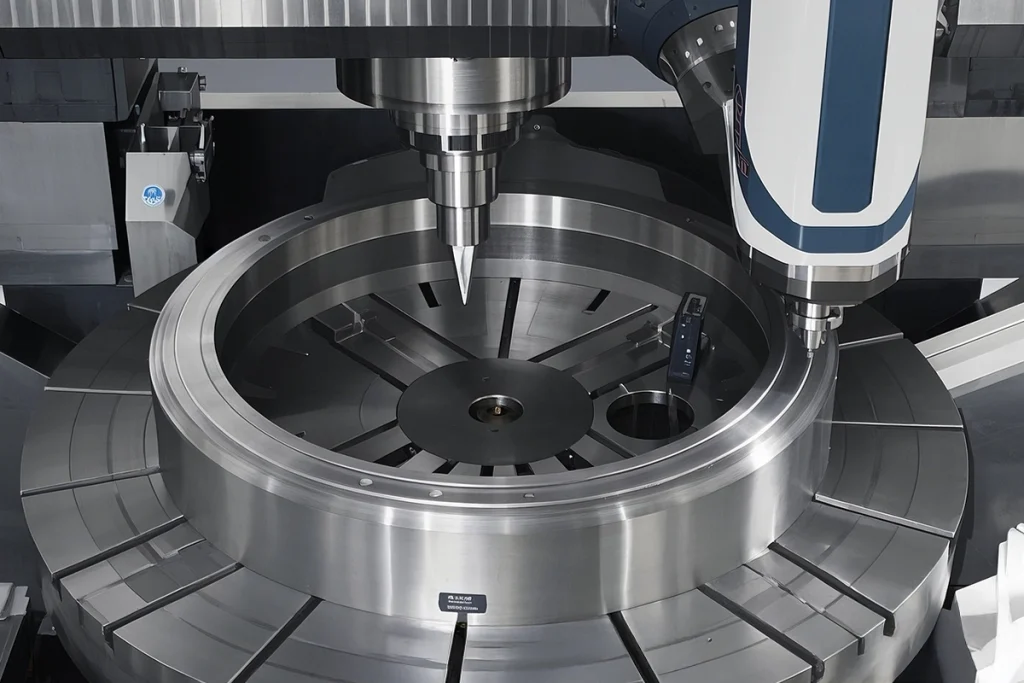

In-house Production

capability with over 100 CNC machines including 5 axis, 3 axis and more.

Quick & Precision

Turn around as fast as 1 day. Tight tolerance up to 0.01mm

7*24 Service

instant customer service. Expert quality control system.

Precision CNC Machining Services | Speed, Precision and Diversity

First Part CNC machining service is a quick and cost-effective approach to manufacture high-grade prototypes, tooling and high-precision end use parts in an array of engineering-grade materials.

At First Part, our unique CNC precision machining capabilities allows you to take advantage of speed, precision, size, cost and even volume. With over 25 engineering-grade materials to choose from, we deliver CNC machining services that allows you to machine parts in your desired material without compromising on cost, functionality and speed. (Click: Factor for CNC machining service) With CNC machining you can meet a wide range of your product development needs. Here are the major benefits of precision CNC machining:

Advantage Of CNC Machining At First Part

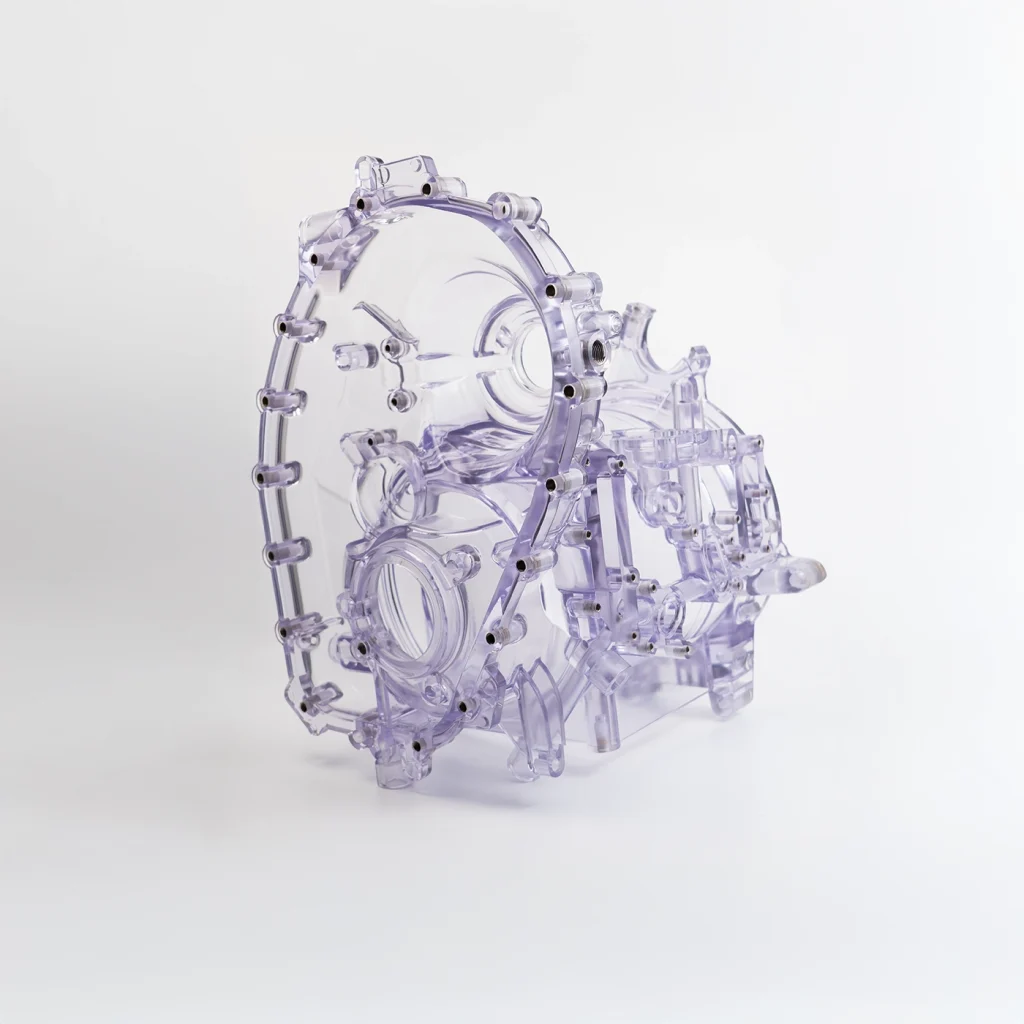

Design Freedom Unleashed

5-axis + EDM hybrid machining creates organic geometries (+67% complexity) without tooling investments.

Predictable Tooling Costs

Dynamic tool wear compensation extends insert life 2.3x, locking your per-part costs for 12+ months.

Thermal Warping Solved

In-process distortion correction using cryogenic cooling, achieving flatness within 0.01mm/m² on large parts.

Supply Chain Transparency

Blockchain-enabled batch tracking from raw material lot to finished part serial number.

Types Of Our CNC Machining Process

Application For CNC Machining

First Part is a leading rapid prototyping, rapid tooling & low-volume manufacturing in the world. CNC precision machining can be applied for:

How To Work With Us

Step 1: Upload A CAD File

Upload your CAD file online & tell us important details about your project to get an instant guaranteed quote.

Step 2: Get Instant Quote & Free DFM

Free Design for Manufacturability (DFM) analysis to suggest design improvements, finishes and processing techniques that are best suited for your project.

Step 3: CNC Machining

One-stop-shop service that ensures that parts remain consistent in their high-quality from start to end with excellent finishes to convey aesthetics, ergonomics and protection.

Step 4: Production & Shipping

Doorstep Delivery – Custom manufactured parts are shipped and delivered to your doorstep in as fast as 3 days.

Why Choose First Part

With over 10 years’ experience in CNC and general machining services, First Part is one of the best rapid prototyping and CNC machining services in China. Here’s why:

Quality & Reliability

First Part is dedicated to meeting high quality standards, delivering part on time with precision, accuracy and reliability. We follow strict quality control systems to ensure that only the best parts are delivered.

Cost-effectiveness & Turnaround

Budget maximization and design optimization to ensure cost-effectiveness and quick turnarounds for low-volume and mass manufacturing.

Capacity & Network

Excellent in-house capacity and capabilities, guaranteeing that your parts are made from top quality from start to finish. Enjoy non-disclosure agreements and take advantage of our network of over 20 CNC machining centres to manufacture parts home and abroad.

Our Strength

Equipment

100+ CNC machines covering 5 axis, 3 axis etc.

Experience

14 years of industry experience, quality guaranteed and Scalability.

Clients

Trusted by our clients, Emerson, Magna, Porsche, Viasat etc.

Price

Service

Quote within 8hrs, 7*24 after-sales service.

See What Our Customers Said

“We have been cooperated with First Part in CNC machining for 6 years. From design to finished product delivery, First Part provides excellent CNC machining professional services and high quality products. Normally, within 12 hours or shorter which helps a lot. We feel they are one of the best CNC machine shop in China.”

Michael P

“When we first requested CNC machining, we tried to contact First Part.They responded within hours with prices, delivery times and suggestions for our requirements. I am really satisfied with their professional service and high quality control. I would recommend them to my friends Without hesitation.”

Kyle Smith

“First Part is our the most satisfactory CNC machine shop. They are high efficiency and high quality control. Since 2016, we have cooperated with them on many projects, they also provided professional CNC machining suggestions to help us complete the projects. That’s why they’re such a great CNC machine shop.”

Jackon Brown

Tolerance Of CNC Machining in First Part

Our precision CNC machining centres can manufacture small to large part sizes with tight tolerances and high precision. Our general tolerance limits for CNC machined metals and plastics is generally affected by the material type and the part geometry. See below our general tolerance limits for metal and plastic materials:

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

With our precision CNC machining machines, we may be able to achieve even tighter tolerances on individual parts. This is however subject to additional costs and price-per-part. Check our quality control information.

| Tolerance Lever | Overall Dimension Range | ||||||

| Specifications | <3, ±0.5 | <6, 3 | <30, ±6 | <120, ±30 | <400, ±120 | <1000, ±400 | <2000, ±1000 |

| Tolerance Standard | |||||||

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

| M | ±0.1 | ±0.1 | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 |

| C | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

| V | — | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |

CNC Machining Materials Options

Our catalogue of materials includes a plastic, metal and composite manufacturing options. We work with metals including aluminum, magnesium, steel, titanium, brass, and more. In addition to our stock material options, Firstpart can source for desired materials and provide machining with customized raw materials that will match the desired application of your part.

Plastic: ABS, ABS+PC, PC, PP, PEEK, POM, Acrylic (PMMA), Teflon, PS, HDPE, PPS, DHPE, PA6, PA66, PEI, PVC, PET, PPS, PTFE and view more plastic materials.

Metal: Aluminium, Brass, Copper, Magnesium, Titanium, Stainless Steel, Tin, Zinc and view more metal materials.

These are the most common materials for CNC prototypes and production parts. In addition, we can work with any type of machinable plastic and metal what you can imagine. Explore our materials and completion options.

The above materials are the most common stock CNC prototyping and production materials. If the desired material is not listed above.Please Click here to contact our team!

CNC Machining Finishing options

- Standard/As manufactured

- Bead blasting

- Sanding

- Anodizing

- Painting

- Chrome-plating

- Electropolishing

- Brushing

- Texturing