8 Ways Manufacturing Will Change In 2021

The year 2020 was no short of surprises. From the global Covid-19 pandemic leading to many businesses’ shutdown to the trade wars between the USA and China, the effects of health, bilateral, and economic challenges have been profound. As the year nears its end, there are ongoing concerns that a new wave of the pandemic […]

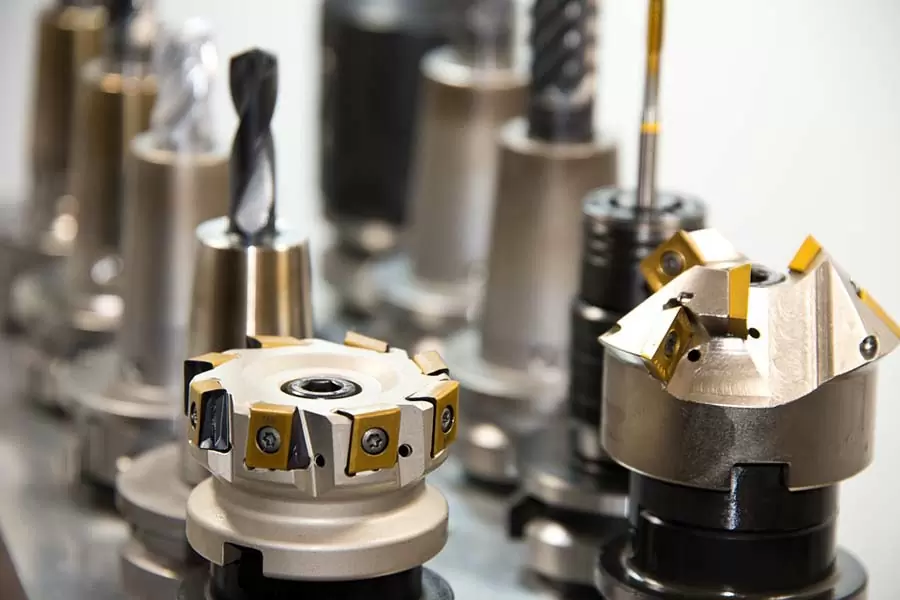

Common Cause of CNC Equipment Downtimes

Operational downtimes are something that every machine shop strives to prevent. At Firstpart, we have successfully optimized our production processes and supply chain to be proactive. As of today, we have successfully gone for more than 36 months since our last downtime. Downtimes can be very costly. This is why we have an agile supply […]

Predicted CNC Machine Trends and Industry Outlook

The CNC machining industry, like the general manufacturing industry, was impacted by several challenges these years. The Covid-19 pandemic resulted in numerous stops and starts, revenue crashes, and worker layoffs in extreme cases. With many manufacturing shops closed for business, predicting the trends for CNC machining can be quite tricky. However, manufacturing continues to remain […]

6 Top Predictions For Additive Manufacturing in 2021

Additive manufacturing, or 3D printing, has been one of the standout technologies of 2020. Even amidst the Coronavirus pandemic, many companies could continue skeletal operations through the simple power of cloud computing, digital manufacturing, and a personal or industrial 3D printer. In this article, we evaluate the likeliest trends for 3D printing along with the […]

Mitigating The Risks Of Sourcing Quality Parts Overseas

China is the world’s global manufacturing capital. Notable businesses like Apple, HP, Microsoft, and more will continue or have at some point looked overseas to source, design, or assemble crucial components in their flagship devices. There are many advantages to sourcing parts overseas. The Asia-Pacific region boasts of scale, expansive supply base, and advancement in […]

Additional Strategies to Minimize Tool Deflection in CNC Machine Operations

Tool deflection is a common pain point in every machine shop. Not only does it cost money to replace your tool, but it can also result in machine chatter, extended leadtimes, and sub-par surface finish in your machined parts. Earlier this year, we covered the basics of tool deflection. In today’s blog, we explore some […]

Low-volume manufacturing | First Part

What is low-volume manufacturing in rapid prototyping? Low-volume manufacturing is a faster approach to the manufacturing of the prototypes of a design in lesser volumes. This type of manufacturing is getting more and more popular in the manufacturing sector due to increased demand for scalable, rapid prototyping. The clients are looking to get ample copies […]

CNC Machining vs Vacuum Casting For Rapid Prototyping

Rapid prototyping has become increasingly popular in product development cycles. Because of the speed and relative affordability, rapid prototyping provides product designers and engineers with an excellent opportunity to quickly test concepts, improve ideas, and accelerate innovation. Today, Firstpart uses 3D printing, CNC machining, and vacuum casting for rapid prototyping. But what drives our choice […]

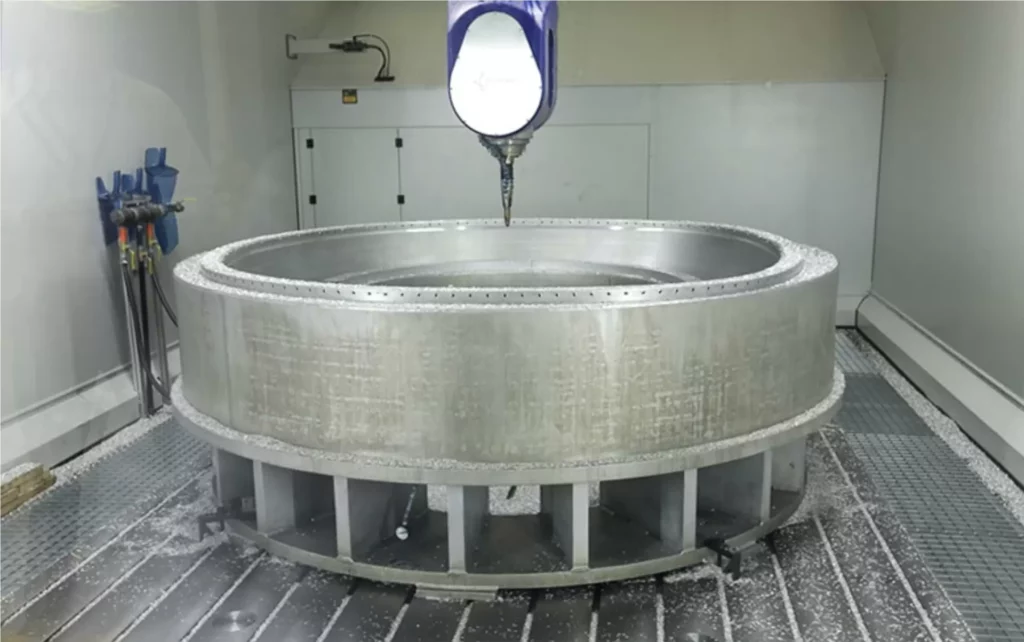

3 Solutions For Making Large Scale Prototypes

3D printing services are almost the industrial staple for making quick product prototypes at affordable rates. With the aid of a design file, a desktop 3D printer, and filaments, businesses can manifest product ideas and concepts in physical forms in as fast as 24 hours. As impressive as 3D printing is, it does have its […]