Knowledge Of Custom Plastic Injection Molding Parameters

Custom plastic injection molding is an injection-molding method. It has the advantages of fast production speed, high efficiency, automation of operation, variety of designs, simple to complex shapes, large to small sizes, precise product dimensions, easy product upgrades, and complex shapes. Injection pressureThe injection pressure is provided by the hydraulic system of the injection system. The pressure […]

Knowledge Of Plastic Injection Molding

Plastic injection molding, also known as injection molding, is an injection-molding method. It has the advantages of fast production speed, high efficiency, automation of operation, variety of designs, simple to complex shapes, large to small sizes, precise product dimensions, easy product upgrades, and complex shapes. At a certain temperature, the completely melted plastic material is […]

What Is Rapid Die Casting?

Die Casting is an industrialized process used in the creation of complex geometry metal fragments by forcing or pouring melted metal into recyclable steel patterns, called dies. These steel molds, also identified as dies or tools are manufactured specifically for each project. They serve as the master copy from which some other copies of a […]

Reducing Part Deformation Aluminum CNC

Reducing Part Deformation in Aluminum CNC Machining Aluminum is inarguably one of the most coveted materials in CNC machining. Its lightweight, high strength, affordability and ease of machinability are all standout attributes, making it perhaps the most used industrial CNC machining material. Even with all of its advantages, part deformation remains a challenge for most Machinists […]

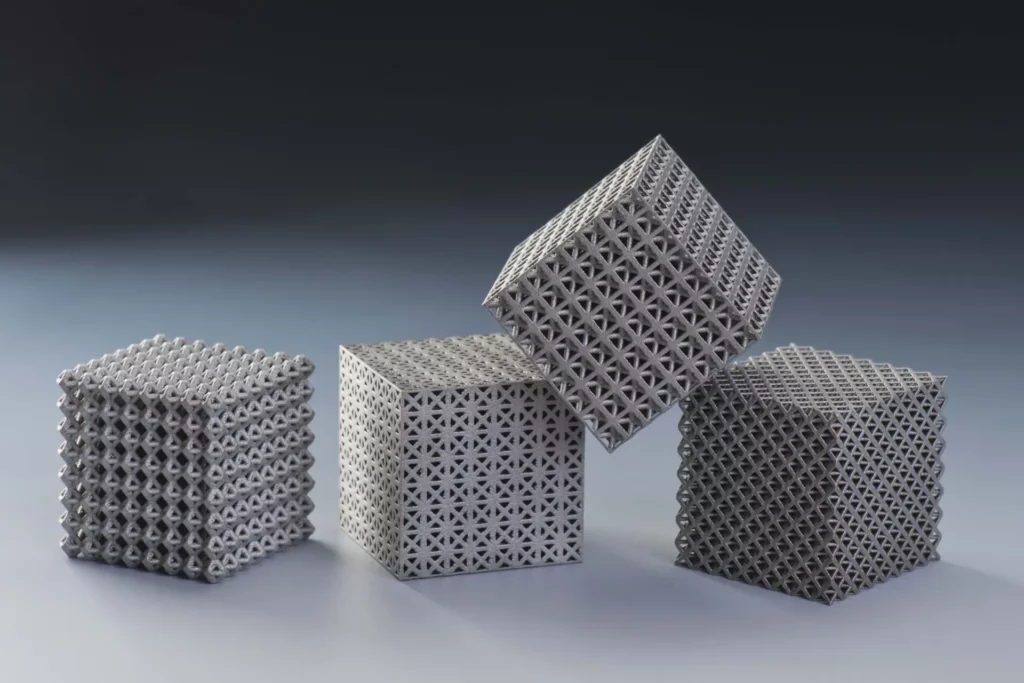

Improving Parts With 3D Printed lattice Structures

Lattice structures refer to repeating units of open two or three-dimensional cell structures that are topologically arranged for specific mechanical and functional purposes. They consist of numerous beams, nodes and struts networked to enhance parts both visually, physically and functionally. Additive manufacturing (3D printing service) allows many design experts to play around the intricate internal […]

Sheet Metal Services And Its Applications

“Sheet metal is a cold operational process for metal sheets (usually below 6mm), including folding, splicing, riveting, shearing, punching/cutting/, forming (such as car body), etc.” Sheet metal is not a definite material. The term is used for metals that have been designed into shape. According to a rule, sheet metal has a rectangular shape and […]

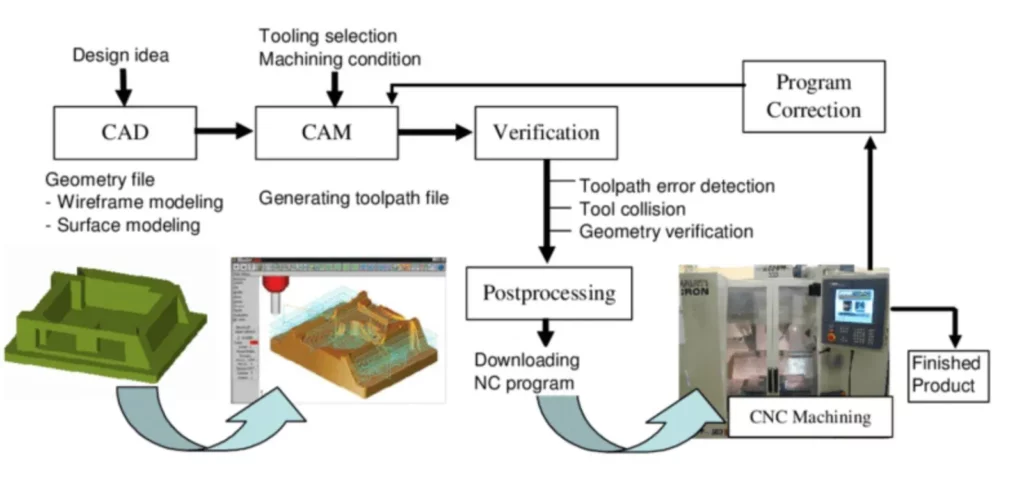

CAD And CAM Design In CNC Machining Service

How CAD and CAM Designs Have Improved Precision CNC Machining Computer aided design (CAD) and Computer aided manufacturing (CAM) are two of the most widely used techniques alongside CNC machining service. These computer aided features have brought about several improvement in design, prototyping and machining over the last couple of years. How exactly do CAD and […]

How CNC Machining Is Changing The Manufacturing Industry

How CNC Machining Is Changing the Manufacturing Industry CNC machining involves the use of computerized controls to remove parts of a material from a workpiece until the final, desired form is attained. Computer numerical control is advancing at breakneck speed; however, the technology is not a new one. Founded in the 700 B.C., CNC machining is […]

Thin Wall Milling

Efficient Thin Wall Milling Techniques Machining parts with thin walls and high dimensional stability is often a dilemma when designing product parts. Parts with thin walls are likelier to have lesser geometric accuracy, stability and straightness. These parts are also more susceptible to breaking, chatter and less likely to have the uniform wall thickness that most […]