How to Control Porosity in Die Casting

Porosity is one of the more serious and most common die casting defects. In die-cast components, porosity refers to small voids, holes or pockets or air spaces that exist within the metal part. As porosity is a structural defect, the effects can be very dangerous. Porosity can result to structural failure, leakage, cosmetic concerns and […]

Injection Molding Project Checklist

Got an exciting project development that involves injection molding? Have you been searching for where to start? Today, we share our top things to consider and consequently, our Firstpart injection molding checklist before requesting for a quote on your new project! First, the basics Before you can understand the requirements in the checklist, you need […]

Some Brief Introduces Of Rapid Prototyping Services

CNC Machining CNC machining is a crucial rapid prototyping service suitable for making high-grade prototypes from either metal or plastics without incurring huge costs. With CNC the machined parts will have smooth surface finishing and tight tolerance in comparison with other prototyping tools or methods. CNC machining yields products to diverse quality with extreme precision […]

Quick Guideline To Get Your Rapid Prototype Done Easier

Manufacturing is a ruthless industry. It demands fast performances from their players and most of them need to meet many conditions related to costs, functionality, and performance that not everyone is willing to comply. A saturated industry for sure, rapid prototyping is always looking for ways to cut costs and become more profitable. The recommended […]

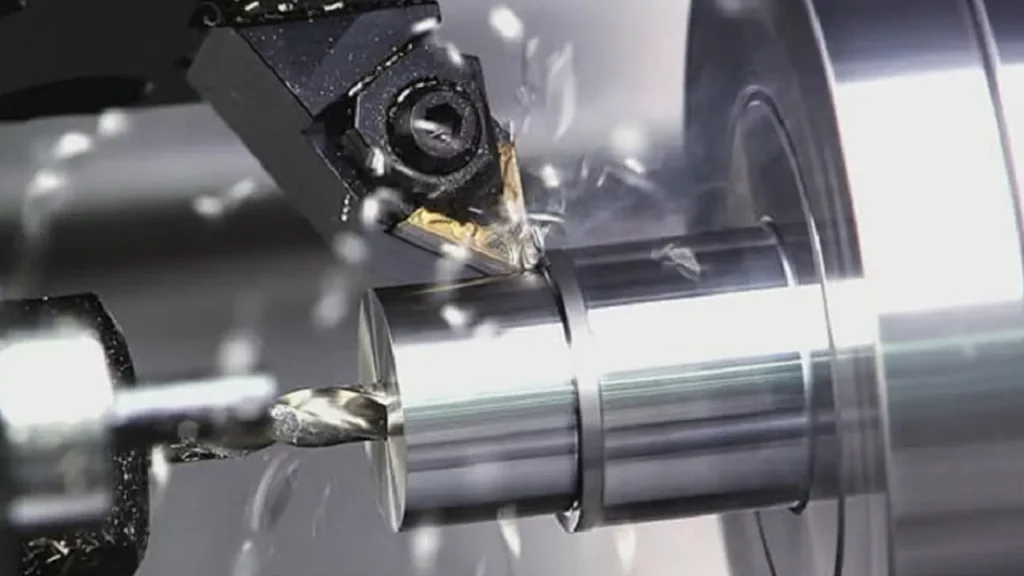

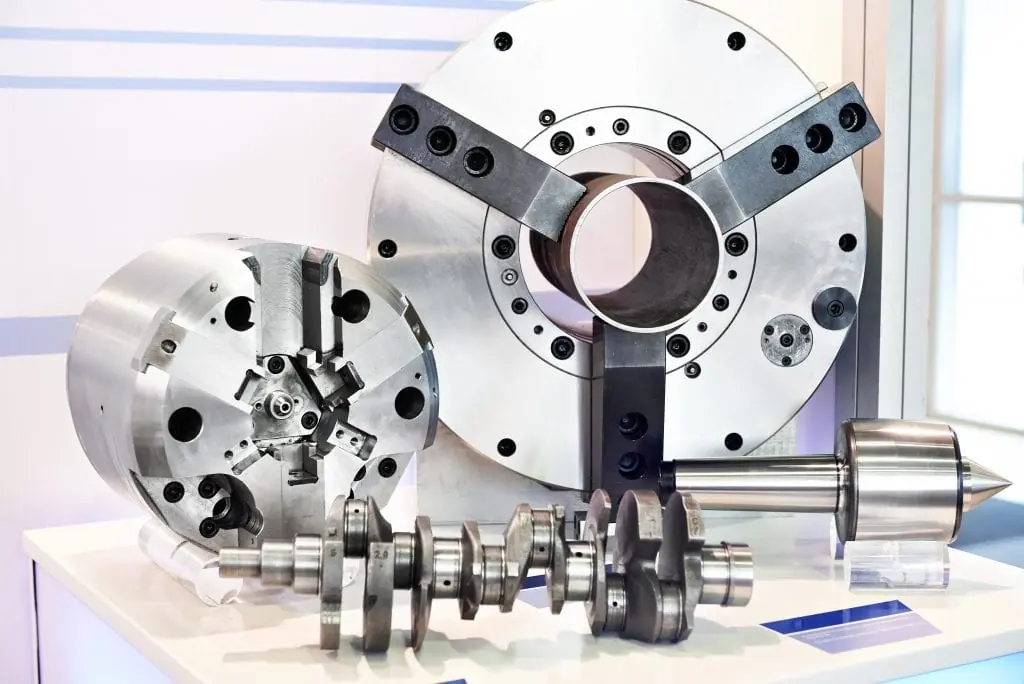

What is the process of CNC Turning?

CNC Turning is an industrial method used to produce parts for several uses and applications. This production technique is controlled through a computer, and the end product is manufactured based on the design programmed in the computer by the operator. Such type of manufacturing is really popular in manufacturing prototypes and internal metal parts for […]

What is the process of CNC Milling?

CNC Milling is best for making holes, pockets, and in general different prototype parts. It has other uses as well, but today we’re not discussing that. Today, we will talk about CNC Milling and its history; along with that, we’ll get to know the types and process of CNC Milling too. So, if you find […]

Cleanroom Injection Molding Operations

Clean room injection molding is a specialized manufacturing process that allows for the production of delicate and implantable medical devices in the most sterile way possible. The injection molding process takes place in a cleanroom environment, which features a high level of atmospheric control through a High-efficiency particle air (HEPA) technology. Cleanroom processes are executed […]

How to Choose Sheet Metals for Rapid Prototyping Applications

Sheet metals play a vital role in many industrial operations. They serve both rapid prototyping and direct manufacturing needs, making them highly rated materials in making different types of products. When it comes to sheet metals, there is no one-size-fits-all approach. This article will take a closer look at the types of sheet metals, their […]

Moving from 3D Prototypes to Injection Molding Ready Parts

Injection molding remains the life blood of large scale plastic manufacturing operations. Because of the heavy capital investment required for molding operations, 3D printing and other solutions are usually employed for prototyping and testing. With 3D printing, you can get the design basics, functionality and aesthetics evaluated at a significantly lower cost than injection molding. […]