How Does Rapid Prototyping Work?

To successfully develop products, most product designers create prototypes for testing. Traditional conventional prototyping may take several weeks to complete product development. Compared to conventional prototyping, rapid prototyping is faster and more cost-effective.Technically speaking, rapid prototyping is a set of technologies used to manufacture models faster than the traditional prototyping process. It can shorten the […]

What are the benefits of rapid prototyping process?

Prototypes are the first full-featured form of new product design, used for investor demonstrations, user testing, and to provide your audience with visual and interactive products. Prototypes can help you understand which features need to be improved to ensure that you can quickly improve the product and bring it to market. The journey from concept […]

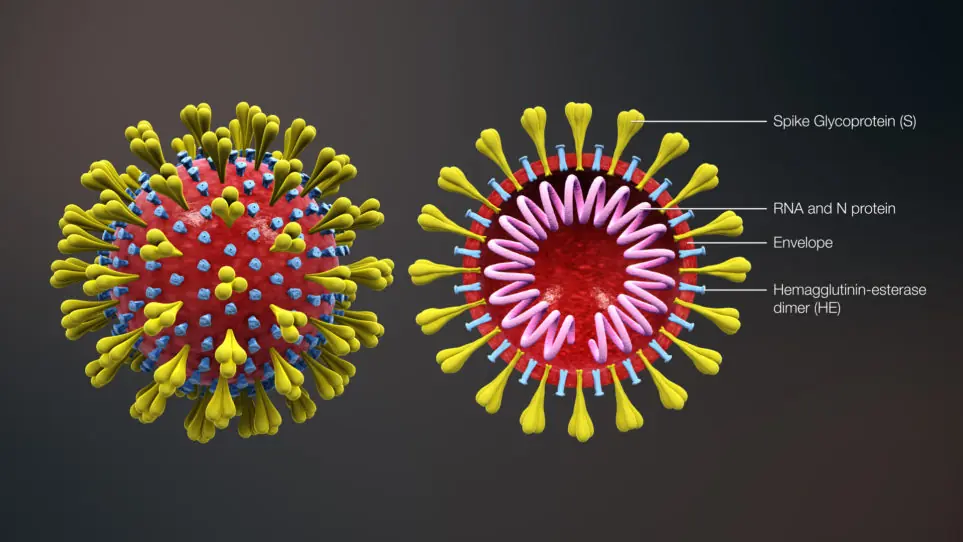

A MESSAGE FROM FIRSTPART ON THE CORONAVIRUS “COVID-19”

The effect of the Coronavirus has on many fronts halted the spin of the world. Over the past couple of weeks, we have seen the world unite in the fight against the pandemic. Several people, organizations and businesses alike have given out in cash, kind and emotions. And as part of our efforts in making […]

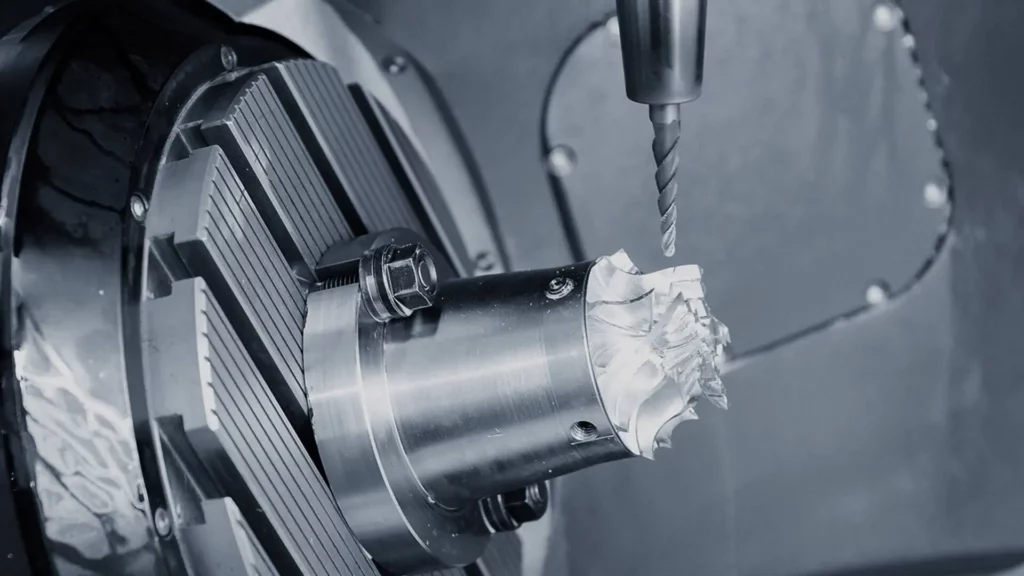

Reducing Heat Generation In CNC Machining

In machining and every other type of contact technique, heat generation is inevitable. In fact, majority of the energy generated in a CNC cutting and milling process is transformed. Heat generation, if not handled properly, can be a tool destroyer. In some cases, heat accumulation in a tool can be easily detected. Other times, heat […]

Dealing With Porosity In Die-casting

Understanding and Dealing with Porosity in Die-Casting Operations Rapid die casting is a metal manufacturing process used to create high-quality metal casted parts with very good dimensional stability and surface finish. The process, which may be used in place of injection molding and machining remains very economical for high-volume manufacturing. And while die-casted parts are often close to […]

Low Volume CNC Production

Milling is the machining development of using the turning cutters that eliminate materials from the workpiece by proceeding in the direction at an angle with the axis of the tool. This procedure of administration covers a wide group of the various machines and procedures on the gauging machine from little machine types to the huge […]