Low-Volume Manufacturing Service

- Leverage hybrid CNC-injection workflows for complex geometries at 30% lower costs

- Enable on-demand manufacturing with cloud-based production monitoring platforms

- Ensure ISO 9001-certified precision across materials from engineering resins to metal alloys

What is Low-volume Manufacturing?

Unlike the situation with prototyping a single unit where most of the clients require more copies for their testing or fund-raising, low volume manufacturing helps to overcome the extra expenditure that usually arises when professionals inevitably need more copies of the prototype. This way, our clients have ample number of units of their design prototype to work with for modification and perfection.

On-demand, Low-volume manufacturing in as quick as 24 hours

Our low-volume manufacturing service was specially created to provide our customers with hundreds to thousands of parts for multipurpose uses. Through 3D printing, Sheet metal Fabrication, CNC machining, Injection Molding, and Die Casting, First Part can facilitate and accelerate your rapid prototyping product development cycles. With an average lead-time of 24 hours, we can manufacture the specified volume of your part for market entry, consumer testing, and bridge-to-mass production.

Our digital capabilities, cross-manufacturing technology, instant quoting system, robust material selection, and finishing services are all part of our competitive advantages. By working with First Part, you can stay ahead of the competition, cut down on production time, and become market-ready in a matter of days! To begin, contact us with your 3D CAD file and receive a free quote here.

If you only need a few prototyping quantities, please click here to explore our rapid prototyping solutions.

Low-volume manufacturing solutions

Depending on the part type to be manufactured, volume, design complexity, we may manufacture 100 to 100,000 pieces for your end-use through

Our 3, 4, and 5-axis CNC machining centers can make high-precision end-use parts in multiple sizes and volumes. Through CNC milling and CNC turning, First Part can produce parts with intricate shapes and geometries for low-volume quantities.

Plastic injection molding can make thousands of plastic parts with an array of resins, colors, and surface finishing. With standard steel tooling and inexpensive aluminum tooling, Injection molding can achieve complex geometries and succinct finishes for any number of parts within 1000 and 100,000.

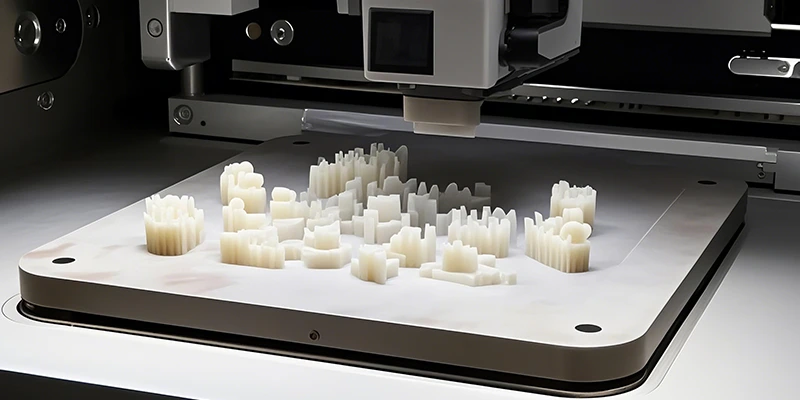

Take advantage of the power of additive manufacturing to make metal and plastic parts in up to 100 pieces for market entry, concept research, and marketing.

Pressure die casting is usually deployed for mass metal production. However, First Part can make copies of aluminum, zinc, and magnesium castings at affordable low volumes rates.

Our sheet metal fabrication allows you to make durable, prototype, and low-volume quantities of your part through bending, forming, pressing, and more. Sheet metal parts have excellent strength-to-weight ratios and can be finished in several ways.

Use the popular 6061 and 6063 alloys, or provide your alloys for our optimized aluminum extrusion process. We use aluminum extrusion to make high-strength, corrosion-resistant quantities of your part quickly and affordably.

Material Options

| Material Name | Common Alloys/Types |

|---|---|

| Metals | |

| Aluminum | 6061, 7075, 2024 |

| Stainless Steel | 304, 316, 17-4 PH |

| Steel (Carbon/Alloy) | 1018, 4130, A36 |

| Brass | C36000 (Free-machining) |

| Titanium | Grade 2, Grade 5 (Ti-6Al-4V) |

| Copper | C11000, C14500 |

| Magnesium Alloy | AZ31B, AZ91D |

| Zinc Alloy | Zamak 3, Zamak 5 |

| Plastics | |

| ABS | – |

| Polycarbonate (PC) | – |

| Nylon (PA) | PA6, PA66, Glass-filled |

| POM (Acetal/Delrin) | – |

| PEEK | – |

| Polypropylene (PP) | – |

| HDPE | – |

| PTFE (Teflon) | – |

| PET | – |

| PVC | Rigid, Flexible |

| LDPE | – |

| PMMA (Acrylic) | – |

| TPU | – |

| PLA | – |

| PS (Polystyrene) | General-purpose, HIPS |

| Epoxy Resin | – |

| Polyurethane (PU) | Rigid, Flexible |

Finish Options

| Surface Treatment | Applicable Materials/Key Details |

|---|---|

| Mechanical Finishing | |

| Sandblasting | Metals, plastics, ceramics (matte/textured finish) |

| Polishing | Metals (stainless steel, aluminum), plastics (glossy finish) |

| Brushing/Linishing | Metals (aluminum, stainless steel – directional grain finish) |

| Tumbling (Barrel Finishing) | Metals, plastics (deburring, smoothing edges) |

| Chemical/Electrochemical | |

| Anodizing | Aluminum, titanium (color dyeing, corrosion resistance) |

| Electroplating | Metals (nickel, chrome, zinc – conductivity required) |

| Electroless Nickel Plating | Metals (no external current, uniform coating) |

| Passivation | Stainless steel (enhanced corrosion resistance) |

| Phosphating | Steel (paint adhesion, rust prevention) |

| Chemical Etching | Metals, glass (decorative/textured patterns) |

| Black Oxide Coating | Steel, stainless steel (anti-glack, mild corrosion resistance) |

| Coatings | |

| Powder Coating | Metals (heat-cured polymer – durable, color options) |

| PVD (Physical Vapor Deposition) | Metals, plastics (thin-film coatings – TiN, CrN for wear resistance) |

| CVD (Chemical Vapor Deposition) | Metals, ceramics (high-temp wear-resistant layers) |

| E-Coating (Electrophoretic) | Metals (uniform primer for automotive parts) |

| Spray Painting | Metals, plastics (custom colors, low-cost) |

| UV Coating | Plastics, wood (fast-curing, glossy/protective) |

| Ceramic Coating | Metals (high-temp resistance, automotive/industrial) |

| Plastic-Specific | |

| IMD (In-Mold Decoration) | Plastics (graphics/textures molded into parts) |

| Laser Marking/Engraving | Plastics, metals (permanent labels, decorative) |

| Vacuum Metallization | Plastics (mirror-like reflective finish) |

| Texture Molding (e.g., EDM) | Plastics (mold surface patterning) |

| Other Treatments | |

| Laser Cleaning | Metals (oxide/contaminant removal) |

| Heat Treatment (e.g., Tempering) | Metals (hardness/strength enhancement) |

| Galvanizing | Steel (zinc coating for corrosion resistance) |

| Hydro Dipping | Metals, plastics (camouflage/pattern transfer) |

| Plasma Treatment | Plastics (improved adhesion for printing/coating) |