Optimizing quality is inarguably the main goal of any injection molding project. This is because part quality impacts a number of metrics that determine the success or failure of that part. Injection molding, in its delicate nature, comprises of 3 steps that can make or break the project. How quality and processing parameters are managed in these steps will determine the functionality, cost and cycle time of your product.

Maximizing part quality translates into less errors, less rework and quicker market entry. So, how do you optimize quality in your injection molding process? Let’s start with the 3 most crucial processes in injection molding – filling, packing and holding. Today, we will take a look at each stage and hint on how you can increase your chances of perfection.

Defining the processes

The overall injection molding process cannot be summarized in these 3 steps. However, the filling, packing and holding steps are the most crucial flow in the molding process. Here’s a quick refresher of what happens in each of these stages:

1. Filling stage

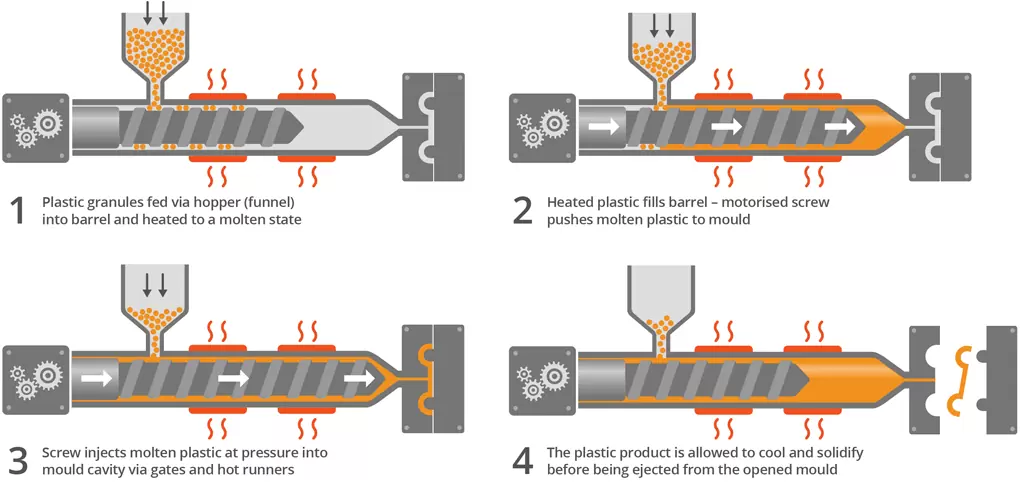

In the filling stage, the molten plastic resin is injected into the mold under the influence of high pressure.

2. Packing stage

The packing stage is a correctional stage. After the initial filling, the pressure is adjusted and more material is introduced into the mold to account for the backflow and material shrinkage that must have occurred.

3. Holding stage

The holding stage is the phase of the process where the material is held at pressure equilibrium. In the holding stage, the gate free occurs, signaling the commencement of the cooling process.

Optimizing Filling

The filling process of the injection molding procedure accounts for the bulk (up to 95%) of the plastic resin material injected into the mold and cavities. In order to optimize this process, it is imperative to:

i. Use the appropriate temperature parameters and specifications for the resin material

ii. Avoid using temperatures too high or too low to mitigate the chances of impurities and imperfections in the finished product

iii. Use the recommend pressure to ensure a smooth, uniform and decent fill rate

Optimizing Packing and Holding

After the filling process is successfully completed, changes in parameters such as pressure, timing and temperature will occur to ensure that the packing and holding processes are optimally executed. While the packing and holding stages are usually grouped together, there is a difference in these two stages, occasioned by timing.

The pack phase is the period immediately after the fill phase, extending till the completion of material filling into the cavity. The hold phase is the phase from the end of the packing to the completion of the gate sealing. In the hold phase, no more plastic is injected.

As noted earlier, the filling stage accounts for 95% of the material in the cavity. The packing or holding pressure is the pressure required for filling the final 5 percent thereabout of a mold tool cavity. In order to optimize pack and hold times, the following tips should be considered:

i. Optimize packing times and pressure to ensure proper formation of the part in high quality

ii. Avoid flash by ensuring that excess material is not injected in the pack phase

iii. Avoid sinks and defects by ensuring that too little material doesn’t remain in the mold after injection in the pack phase

iv. Carry out effective gate seal study to measure product weight relative to time. Use the data here to tweak the time and pressure until the exact product weight and desired material in the mold is attained.

There are special scenarios where timing and pressure will differ in the pack and hold stages. These situations can occur in:

i. Softer plastic resins

ii. Hot runner molds

iii. Valve-gated molds

iv. Molds with large gates and gigantic molds

In these instances, conduct separate weight-time evaluations for each phase and adjust the pressure subsequently for the holding stage to ensure that the weight stays constant all through the process.

First Part Injection Molding Services in China

FirstPart offers high quality, thermoplastic injection molding service for all your plastic part projects in China. We also offer low-volume manufacturing that serve small quantities from 50 to 10000 parts and produce for mass production. Our engineers are always available to advice on the best processes, materials and design optimization to ensure cost-savings, quick turnaround and the production of parts that are 100 percent defect and issue free.