3D Printing in Healthcare and Medicine

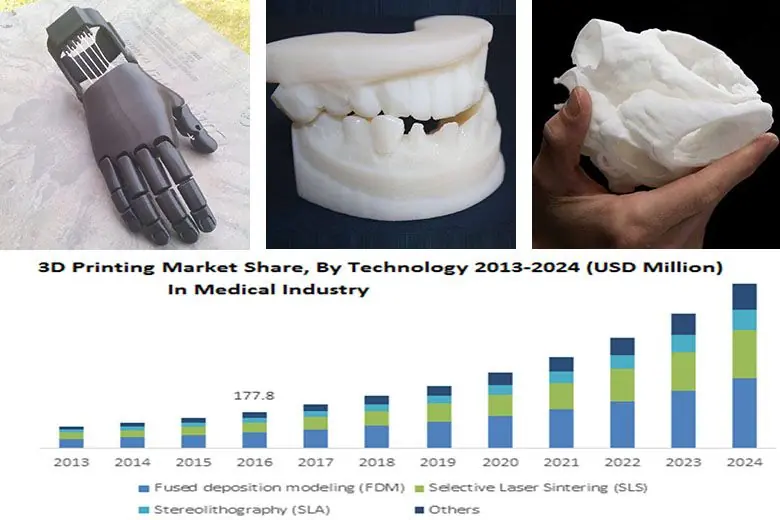

Medicine and healthcare have seen more involvements with 3D printing over the last decade than years before then. 3D printing has pushed the bounds of conventional medicine, creating opportunities to explore solutions that have led to huge breakthroughs in the field of medicine.

From the most complex organs such as the human heart and liver to prosthetic arms and legs, 3D printing is giving many people a second chance at life, an opportunity for survival and functional solutions at more affordable costs. Let’s learn how 3D printing has revolutionized the healthcare and medical industry.

1. Organs

With the aid of 3D printing, vital organs such as the heart and liver have already been reproduced to facilitate medical transplants. While an entire organ has not been fully 3D printed, Medical Engineers have perfected and successfully produced and 3D printed cells that function just like the natural equivalent of these organs.

Layer by layer, a medical research at Carnegie Mellon University have printed a human earth with bio-like material, putting materials such as fibrin and collagen to use. Although none of these 3D printed organs have been successfully transplanted as a full replacement in people, the breakthrough is just around the horizon and 3D printing is more likely than ever to deliver.

2. Limbs and Appendages

In countries, bacterial infection often spreads faster than medical treatments, often leading to amputation of appendages and limbs. Other reasons for amputations may include diabetes or accidents. With 3D printing, medical engineers can now create low-cost prosthetics in faster time than conventional prosthetics.

Today, getting prosthetic solutions for limbs and hands is easier than ever. Because 3D printing is largely customizable, patients get to obtain bespoke prosthetic attachments that are ergonomic and well suited for their needs. Through 3D printing, prosthetic rib cages have been made to treat cancer patients whose tumor related to that area has required a removal of his natural rib cage.

3. Bones

3D printing has facilitated the treatment of bone issues and osteoporosis in many ways.

Doctors can now 3D print bone-like material that serve as support materials that is uses in orthopedic process. These 3D printed bone materials can also be used as a skeletal support system to support old bones that are healing or to propagate the growth of new bones. These 3D bone-replacement tissues are harm-free and will dissolve on their own as soon as the new bone is fully in place.

The cranium, the biological shell that protects the brain has also been successfully transplanted with the aid of 3D printing with medical grade titanium material. Without 3D printing, some of these surgical procedures will have been almost impossible or significantly more complicated.

4. Cells and Tissues

3D printing can help medical experts reproduce body-like cells and tissues that can be used to treat cellular diseases, spinal injuries, stroke, diabetes, arthritis and more. These 3D printed cells and tissues may be injected as fillers into affected areas to support and regulate the function of the damaged tissues such as stem cells with regenerative abilities.

5. Medical Tools

3D printing can be used to design and create a wide array of medical-grade surgical tools. With additive manufacturing, 3D printing makes it possible to get medical devices that are otherwise difficult to obtain in complex geometries and at affordable prices.

Using a sterile printer, parts such as umbilical cord clamps, inserts, scalpel handles, tubes and valves and much more are manufactured to deliver precise and accurate treatments.

Firstpart 3D Printing Prototype Service in China

As one of the top manufacturers in China, FirstPart encourages you to try out our high-quality online 3D printing service solutions and get started with your first 3D project. Our engineers are available to help with a free quote and design evaluation. Depending on the nature of your project, you will typically receive your quote in a number of hours as well as several suggestions on how to optimize your end part. FirstPart also provides stringent quality control evaluations and super-efficient logistics that guarantees that you receive your 3D printed objects, produced to specifications as desired, quick and intact.