Precision, Safety and Quality

Prototyping

Agile Manufacturing for Medical Device Innovation

For years gone by, First Part has shown an uncompromising dedication to improving and building a healthier world for everyone. Through our high-quality industrial applications of 3D printing, injection molding, polyurethane casting, precision CNC machining and a diverse range of finishing options, First Part has helped many stakeholders in the medical industry innovate patient-tailored devices that aid and abet diagnosis, improve treatment and save lives.

Our medical manufacturing services are especially dedicated to the production of medical devices, surgical equipment, precision parts, meter device components, dental solutions, orthopaedic implants, bone substitutes, bone plates, prosthetic devices, prosthodontic screws, smart glasses, fitness trackers, drug-delivery devices, health monitor devices, test kits, PPE, control units Corrective Insoles and Orthoses. Our expertise in the dental industry has also birthed several collaborations in the production of dental implants, dental prostheses, implant abutments, artificial teeth and bridges, and implant screws.

Agile Manufacturing for Medical Device Innovation

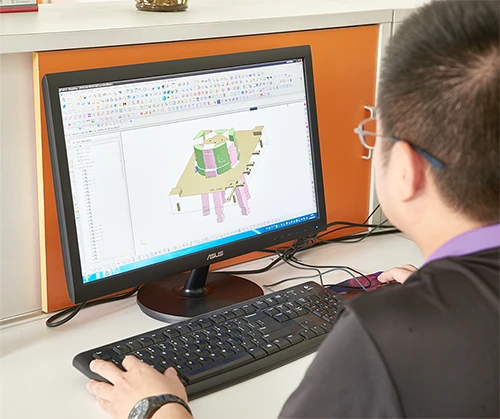

DFM Analysis

With First Part, you receive a design-for-manufacturing (DFM) analysis on every project, highlighting opportunities for better and improved design that saves time and money.

Low-volume manufacturing

Mitigate budgetary constraints with our low-volume manufacturing services for making 1-1,000 parts in as fast as 24 hours.

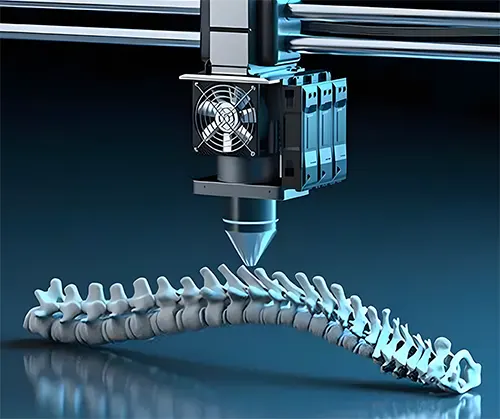

Rapid prototyping

Use 3D printing and precision CNC machining to make high fidelity prototypes and deliver personalized solutions unique to the circumstance of each patient. Using sterilizable, non-corroding and biocompatible materials, you can prototype and tool certain devices that will deliver more accurate cuts, shape patient implants or replace certain fractured parts of the body before operations.

Bridge tooling

Become fail-proof by using affordable bridge tooling options to evaluate high-fidelity prototypes in early markets before capital investment for mass production.

Cross-technology range

Take advantage of diverse manufacturing techniques and production portfolios to ensure that your parts are made with the best technology and most ideal materials.

Material options

Choose and leverage the strengths of medical metal alloys, medical-grade silicone rubber, 3D printing filaments, resins, elastomers and high-temperature plastics to deliver functionality in all your parts.

Common Medical Manufacturing Services

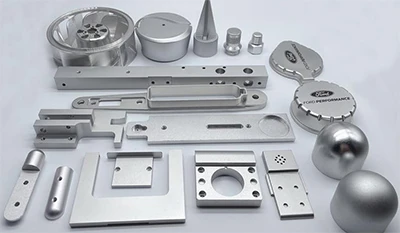

CNC Machining

High-precision subtractive manufacturing for medical-grade metals (e.g., 316L stainless steel, Ti6Al4V). Delivers ±0.025mm tolerances, mirror finishes (Ra <0.4μm), and ISO 13485-certified surgical tools, implant prototypes, and MRI-compatible components.

Rapid Injection Molding

Low-volume thermoplastic production (1-10k units) using aluminum molds. Processes biocompatible resins (PC, PP) for nasal swabs, fluid connectors, and disposable housing. Achieves 2-4 week lead times with FDA-compliant surface finishes.

3D Printing

Patient-specific solutions via DMLS/SLA: porous titanium implants, anatomical models (MultiJet photopolymers), and sterilizable surgical guides. Supports ISO 10993-certified materials with 150μm layer resolution for complex geometries.

Urethane Casting

Silicone-mold-based duplication for soft medical components: cushioning pads, ergonomic grips, and biocompatible prototypes. Uses medical-grade urethanes (Shore 20A-80D) to mimic final materials at 1/3 the cost of injection molding.

You Can Trust Us

Client Base

500 Companies

2M+ projects

Cross Industry Experience

Medical & Dental, Aerospace, Defence, Automotive, Consumer Electronics, Agriculture, Engineering, Robotics, Construction.

Experience

10+ years of active business operations

Reach

Over 30 Countries served

FAQs – Frequently Asked Questions

What are the most common medical and dental applications?

| Surgical equipment | Prosthetics |

| Meter/monitor device components | PPE |

| Handhelds | Testing kits |

| Wearables | Drug-delivery devices |

| Cartridges | Dental implants |

| Housings and enclosures | Bone substitute components |

| Implants |

What are the best materials for medical applications?

Titanium

High-strength internal joint and skeletal substitutes. Titanium is strong, temperature resistant, 3D printable, lightweight and corrosion resistant.

Stainless steel and Inconel

Various alloys of steel being their temperature resistance, strength and corrosion resistance. Ideal for swiss-type surgical equipment.

Medical-grade silicone rubber, TPE

Used in the manufacture of custom fittings and seals. These materials have laudable electrical, chemical and thermal resistance. They are bio-compatible, making them suitable for applications that may involve skin contact.

POM, PEEK, PEI

PEEK is a heat-sterilizable material that can be used as high-performance plastic. PEEK, POM and PEI are all suitable for use as joint replacements. They are high temperature and creep resistant, and sterilizable.

Nylon and ABS

Excellent for use in medical appliances. These materials are 3D-printable and very affordable.