Plastic, Metal & Elastomeric Components

Rapid Prototyping, Rapid Tooling & On-demand Production

Global Delivery in 7 days

Prototyping

Accelerate Hardware Development, Mitigate Risks & Build An Agile Supply Chain

Unlike software development, the risks and engineering involved in hardware startups and product development can be challenging. Iteration may be limited for startup companies due to budgetary constraints, technological capacity, and competitive timelines.

At First Part, we strive to help hardware startups level the playing field. Our low-volume manufacturing services and rapid prototyping solutions are ideal for quick testing, pilot runs, design iteration, and marketing showpieces to investors. Our engineers’ expertise from building with hardware startups over the years is available to make critical design evaluation, perform design-for-manufacturability analysis, and exploit opportunities to help you shorten your product development cycles.

Why You Should Work With Us

Speed

We offer a myriad of finishing solutions to convey the much-needed beauty and aesthetics seen in premium consumer electronic parts. Our finishing solutions will increase user acceptance scores and drive variety in your product lines, making sure there is something for every customer. From anodizing to polishing, coating, texturing, media blasting, and unibody finishes, First Part is a one-stop-shop.

Low-volume solutions

First Part has flexible production volumes that help startups and hardware companies to spread their budget and deal with financial constraints. With zero minimum order quantities "MOQs," First Part can make 1-1000 parts at competitive rates.

Instant quoting

Our instant and free quoting service can help you truncate wait lines and get your first quote in a matter of hours. Simply upload your design file, and our automated quoting engine will perform a design evaluation and relay pricing as quickly as possible.

Design-for-manufacturability

First Part conducts a free design-for-manufacturability analysis on your part design to explore opportunities for cost savings, improved functionality, and enhanced performance.

Rapid tooling

Reap the benefits of our robust quality systems, ISO 9001:2015, AS9100 certification, and precision measuring components to get only the best parts for your hardware.

Quality Control And Standards

Reap the benefits of our robust quality systems, ISO 9001:2015, AS9100 certification, and precision measuring components to get only the best parts for your hardware.

Experience

Tap into the wealth of experience in our engineering teams to help you innovate, prototype, and test as quickly as possible. With over ten years of industrial manufacturing for electronics, semiconductors, chipsets, robotics, automotive, energy, and medical components, our multisector and multidisciplinary knowledge will come to the fore in improving your part design and functionality.

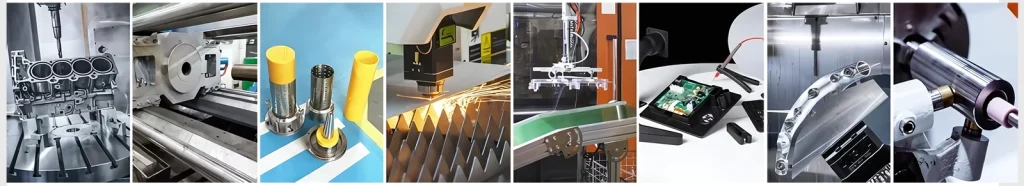

What Technologies Do We Use To Make Hardware Components?

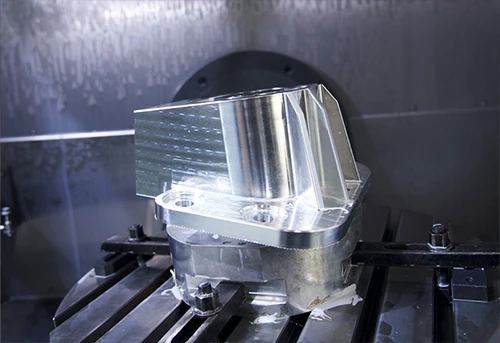

CNC Machining

Rapid-turn metal prototyping (24-72hrs) with ±0.05mm tolerances. Ideal for robotic joints, drone motor mounts, and sensor housings in 6061-T6 aluminum or 316L stainless steel. Scale from 1 to 500 units without tooling costs.

Rapid Injection Molding

Low-volume (500-5k units) ABS/PC parts with 48hr mold turnaround. Produce IoT device enclosures, wearable buckles, and waterproof gasket seats at 1/3 traditional mold costs. FDA-grade finishes for crowdfunding demos.

3D Printing

Functional prototypes in 12hrs: carbon fiber drone arms (Onyx+CF), heat-resistant engine ducts (ULTEM), and snap-fit connectors (Nylon 12). Zero tooling, unlimited design revisions – perfect for pre-seed validation.

Urethane Casting

Soft-touch prototypes (Shore 30A-80D) for button pads, vibration dampeners, and ergonomic grips. Silicone molds ready in 3 days, 50-300 units at $5/part. Test user experience before hard tooling.

We are here for we always give you satisfaction

You Can Trust Us

Client Base

500 Companies

2M+ projects

Cross Industry Experience

20 different industries

Culture And Diversity

10+ Languages

Experience

10+ years of active business operations

Reach

Over 30 Countries served

Hardware & Startups FAQs – Frequently Asked Questions

What Parts Can First Part Make?

We can make an array of hardware components that will serve as either part of a more significant project or the main project itself. Our material options allow us to fabricate parts for:

| Chipsets and Semiconductors | Chassis, brackets, and enclosures |

| Automotive hardware | CPUs and GPUs |

| Exterior unibody and housing compartments | Buttons, dials, and haptic sensors |

| Drives, ports, fans, heat sinks | Mobile device components |

| Wireless device modules | Laptop screens and external accessories |

| Printed circuit boards (PCBs) | Sensors and actuators |

| Hardware panels and ICUs | Medical devices |

What Materials Are Available For Hardware Manufacturing?

| Natural and synthetic rubber | Elastomers |

| Thermoplastics | Aluminum |

| Titanium | Brass |

| Nickel | Zinc |

| Silver | Chrome-cobalt |

| Copper | Stainless Steel |

| Inconel |