Our rapid prototyping, rapid tooling, and rapid injection molding solutions are applied in multiple industries.

Enable lightweighting strategies and EV subsystem validation through high-tolerance rapid tooling for underhood components and structural composites.

Achieve ISO 13485-certified tooling for biocompatible components and microfluidic systems with chemical-resistant surfaces.

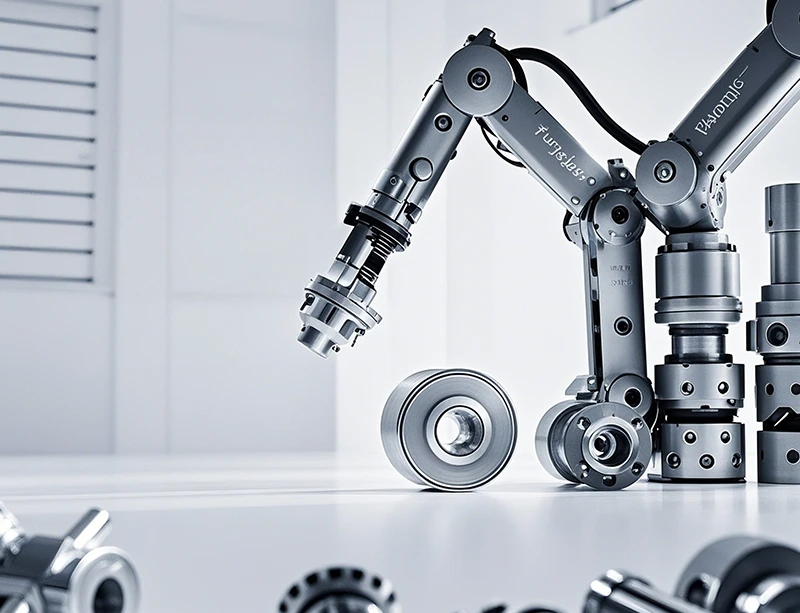

Achieve motion-ready assemblies through precision-machined actuator housings and IP-rated robotic end effector tooling.

Optimize ergonomic designs through glass-filled nylon prototypes and overmolded grip tooling.

Implement multi-material molding for soft-touch interfaces and UL-certified enclosures with integrated EMI shielding.

Enable micro-injection molding for sub-2mm wall thickness enclosures and RF-transparent antenna components.