ELECTRONIC PARTS MANUFACTURING

Nanoscale innovation unleashed: AS9100-compliant rapid prototyping with high-quality metrology & MIL-STD-883 class H reliability for quantum era components.

Build Smarter Electronics, Broaden Product Offerings and Improve Chipset Performance

First Part can help your business cope with the fast-paced innovation in consumer electronics, semiconductors, and chipset technology. As we continue collaborating with market leaders and emerging companies in building user-centric designs, our manufacturing solutions like CNC machining continue to push the frontier of chipset production. Today, Firstpart can manufacture varying components of consumer electronics, household goods, smartphones, laptops, TV sets, Video game consoles with high accuracy and precision.

Our engineers will perform a free design evaluation on your product to suggest areas of improvement for enhanced ergonomics, reduced power consumption, and better consumer experience. With our rapid prototyping and low-volume production offerings, product designers can accelerate their product development cycles, speeding from ideation to design validation and physical prototypes in as fast as 24 hours. Explore our services and see how our on-demand production and finishing solutions can help you broaden your product SKUs, offer more variety and get to critical markets ahead of your competition.

Why You Should Work With First Part

Design Analysis

First Part conducts a free design for manufacturability analysis on your part design to explore opportunities for cost savings, improved functionality, and enhanced performance.

Finishing Solutions

We offer a myriad of finishing solutions to convey the much-needed beauty and aesthetics seen in premium consumer electronic parts. Our finishing solutions will increase user acceptance scores and drive variety in your product lines

Rapid Prototyping

We offer rapid prototyping solutions through CNC machining and 3D printing to make quick iteration of electronic components for marketing, design validation, mock-ups, and functional testing and analysis.

Low-volume Production

Our low-volume production solutions can make up to 1000 units of your part without hard tooling for pilot tests, simulation runs, and showcase/exhibitions.

Mass Customization

With 3D printing and CNC machining, First Part can help you make diverse user-centric designs with subtle or emphasized differences to ensure that your part captures every segment of your target audience.

Quicker Leadtimes

The speed of our CNC machining, 3D printing, and rapid tooling all ensure that you can land final prototypes and low volumes of your parts within the space of 1-7 days.

Zero MOQs

With zero minimum order quantities, Firstpart can work with all ranges of budgets to build as little as one part up to a thousand for rapid prototyping, classroom learning modules, laboratory practical lessons, and R&D.

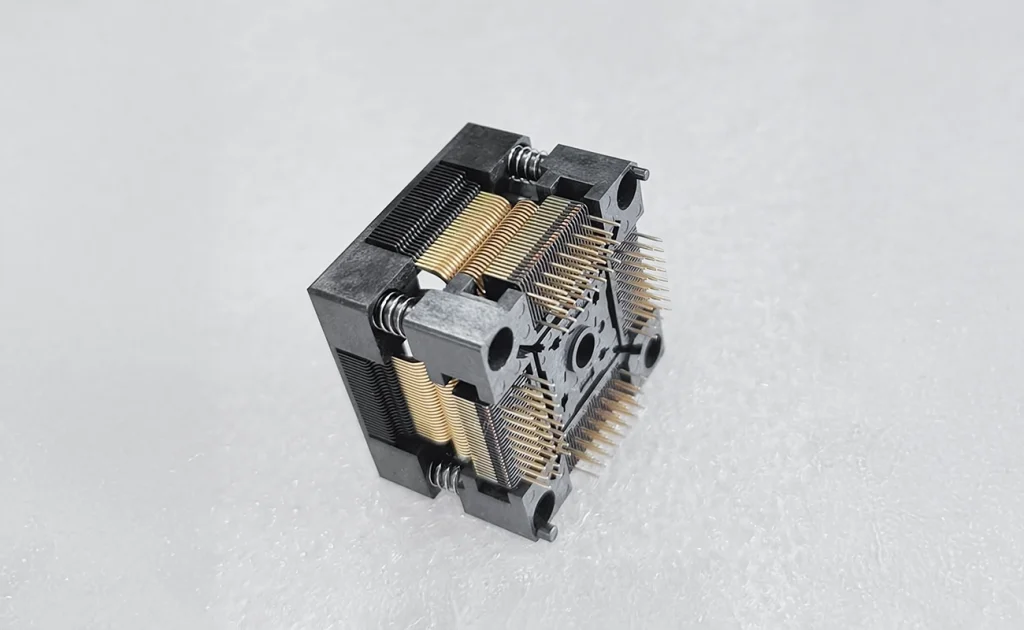

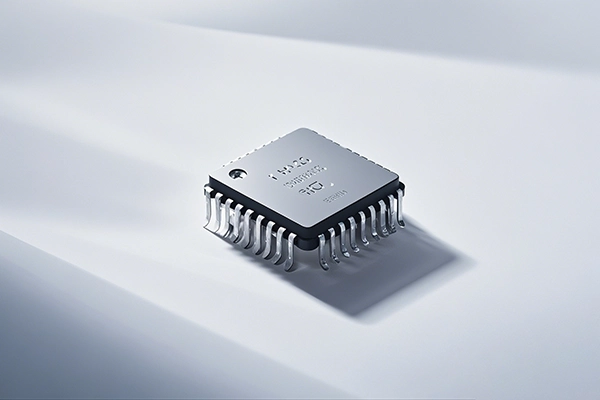

What Electronic Parts and Components Can Firstpart Make?

Consumer electronics and semiconductors require dimensional excellence, geometric perfection, and tight tolerances for improved performance. Whether you aim to make user-friendly household parts, high-end supercomputing chipset, nanometer smartphone CPUs, and many more, Firstpart can manufacture parts and components for every consumer electronics category. Here are some of the things we can make for you:

- Semiconductor components

- Chipsets

- CPUs and GPUs

- Heat sinks

- Cooling fans

- Printed circuit boards (PCBs)

- Enclosures, chassis, brackets, and housings

- Mobile phone accessories

- Laptop parts and Camera gadgets

- Tripods

- Sensors and actuators

- Wireless devices, headphones, and smart home devices

- Sport and fitness wearables

- Battery components

- Security and alarm components

- Consumer electronics

- Smartphone manufacturers

- 3rd party mobile device accessories

- Computer and Laptop manufacturers

- Smart devices, electronics, and home equipment

- Smart home engineers

- Robots and processing lines manufacturers

- Smartwatch and wireless device engineers

- Chipset, circuit, CPU, and GPU companies

- Motherboard and PCB engineers

- Security systems and commercial electronics

- Sensing devices and digital gauges

- Sound and music equipment companies

What Materials Are Available For Electronics & Semiconductors?

Elastomers

- Polyurethane

- Liquid silicone rubber

Thermoplastics

- Nylon

- PEEK

- ABS

- PC

- PS

- PU

- Acetal

- Acryilc

- PVC

Metal and metal alloys

- Aluminum

- Nickel

- Cooper

- Silver

- Tin

- Zinc

- Chromium

- Silicon

- Stainless steel