Choosing Between Soft And Hard Tooling Injection Molding

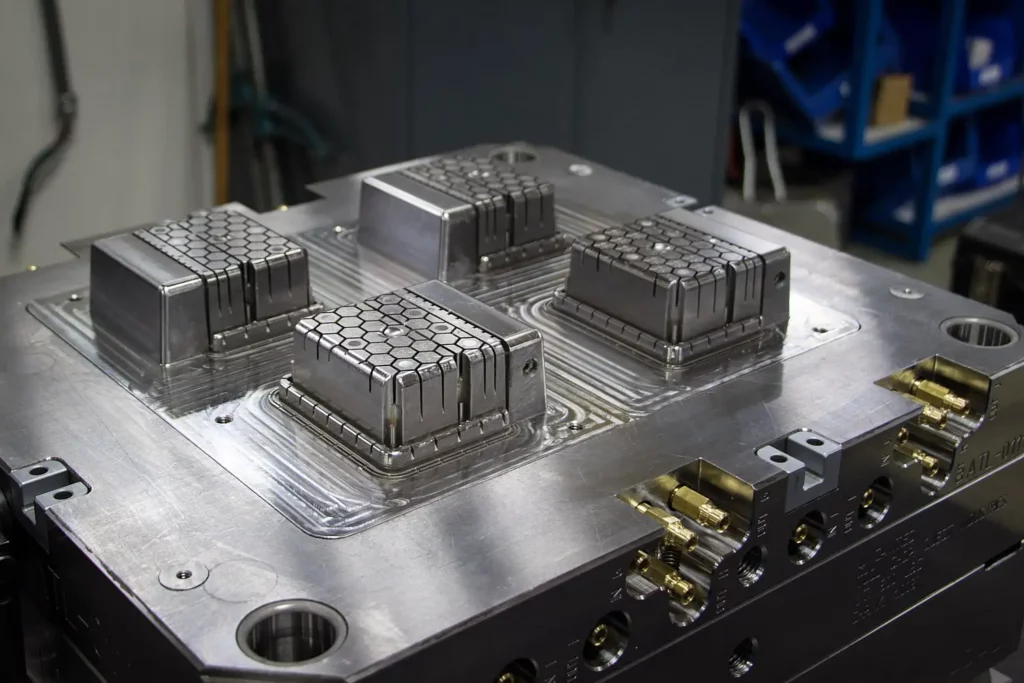

Choosing Between Soft and Hard Tooling Injection Molding Injection molding solutions exist across different production and volume needs. Generally, injection molding tools may be produced via soft or hard tooling. Tooling is the skeletal system of every manufacturing and injection molding operation. It is simply defined as the production of various components and accessories that […]

Workpiece Loading Options For CNC Machining

Workpiece Loading Options for CNC Machining It is almost impossible to highlight the importance of securing a workpiece before commencing any machining work in your workshop. Workpiece loading involves the methods and procedures carried out to load and hold a workpiece during manufacturing. It is all essential process that can help mitigate several risks around […]

Understanding Design For Assembly

Design for Assembly (DFA) Guidelines for Product and Prototype Development Design for assembly (DFA) is the umbrella term for the set of rules that govern part and product design. Design for assembly guidelines work along with design for manufacturing (DFM) rules to ensure that each part is manufactured to specifications, avoid material waste, optimizes machining […]

5 Solid Tips To Help You Create The Ideal BOM

5 Solid Tips to Help You Create the Ideal BOM The Bill of Materials (BOM) refers to a detailed and thorough list of raw materials, quantities required, assemblies, components, sub-assemblies and parts required in the engineering and production of a product. It is a document that gives a comprehensive overview of all the items required […]

BASIC INJECTION MOLDING MAINTENANCE TIPS

BASIC INJECTION MOLDING MAINTENANCE TIPS As more and more units of plastic parts are manufactured with your injection molding machine, fatigue, wear, tear and depreciation begin to catch up with the machine. These factors inevitably reduce the lifespan of the machine, slowing down its output, reducing leadtimes, increasing the likelihood of errors and degraded production […]

5 Hacks For Maximizing The Impact Of Your Product Prototypes

5 Hacks for Maximizing the Impact of Your Product Prototypes The importance of rapid prototyping in any product development cycle is inexcusable. Prototyping remains the only practical solution for evaluating design, functionality and user acceptance before embarking on mass production and introducing the product to the intended market. This is why prototype evaluation can be […]

5 Solid Benefits Of 3D Printed Living Hinges

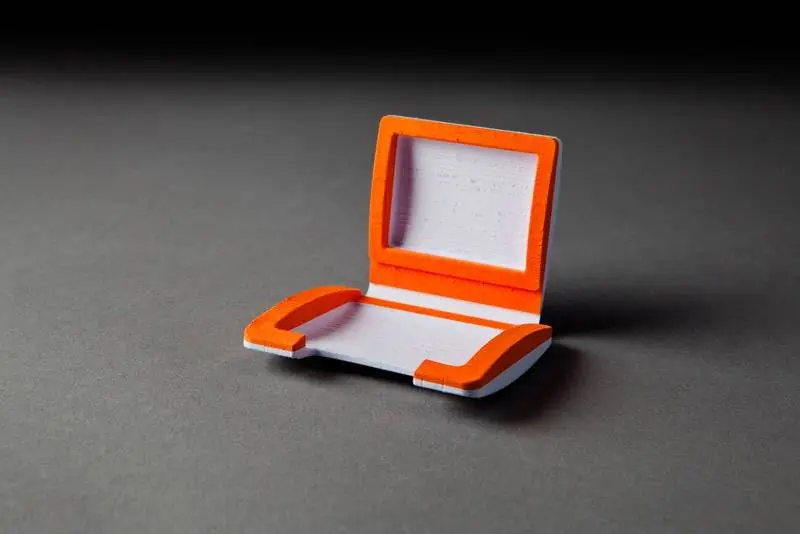

5 Solid Benefits of 3D Printed Living Hinges Living hinges in consumer products refer to the simple, flexible plastic part that connects two or more rigid sections in your design. They are affordable, minimalist and highly functional, making them the go-to solution in a wide array of commercial products. From shampoo bottles, to Airpod cases, […]

Short Descriptions Firstpart

Low-Volume Manufacturing At Firstpart, we provide low-volume manufacturing services to fast track your product development and prototyping needs. With 3d printing, urethane casting, CNC machining, vacuum casting and sheet metal services, our expert team of engineers can manufacture anywhere between 10-10,000 units of your part. Our low-volume manufacturing is a popular option for product engineers, availing […]

Understanding Draft Angles In Die Casting

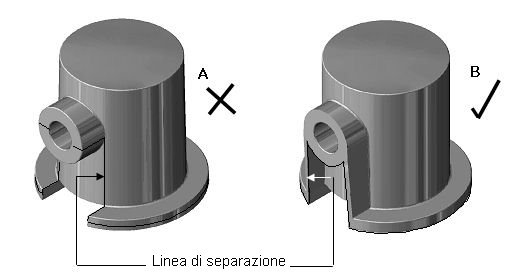

Understanding Draft Angles in Die Casting Die casting is an industrial manufacturing process used in the mass manufacture of components, critical and end use parts that serve various purposes. The process basically involves the introduction of molten metal into a mold cavity at very high temperatures. The injected molten metal is then left to cool […]