Introduction to Geometric Dimensioning and Tolerances

If you are conversant with the CNC industry, GD&T is a term that you will have heard at least once. In the simplest way possible, GD&T refers to geometric dimensioning and tolerances, a system or language of symbols used by CNC machinists to communicate how to effectively translate a design into a physical functional part. […]

6 Industrial Applications for Stainless Steel

Stainless steel is right at the heart of engineering and construction applications. Through fabrication processes like cutting, punching, welding, forming or CNC machining, stainless steel materials can be processed from raw stock into appliances, pipelines, kitchenware and countertops and many more. Although stainless steel is gradually being replaced with aluminum, titanium and some other metal […]

Essential Machinist Tools for Every Workshop

One of the pillars of success in machining operations involves using the right tool for the right tasks. In CNC machining, where projects vary in size, geometry and finish, it is ideal to have an idea of the different types, classes and variety of tools for every workshop. Depending on what you’re trying to achieve […]

The Most Common Metal Fabrication Terms in Sheet Metal Processing

Sheet metal fabrication is a simple yet diverse manufacturing operation. For product designers, companies and entrepreneurs that are new to interfacing with sheet metal companies, there are a number of terms denoting key operations you should know. From design to production and assembly, these terminologies will remain pervasive in your discussions, and having a full […]

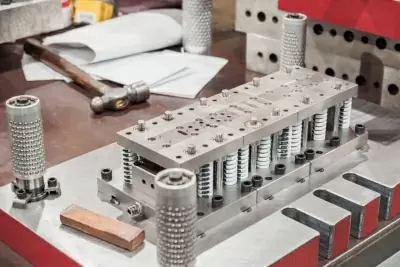

What are the Benefits of In-house Tooling?

For Injection molding operations, tooling is a big initial investment that must be perfected before molding operations commence. This is because the tooling is the framework for the thousands of parts that will result from the mold. A single defect in the mold tool will be replicated across all the parts produced from that tool. […]

6 Great Tips to Get the Perfect First Layer in 3D Printing

Unlike subtractive manufacturing techniques, 3D printing builds prototypes and parts from the ground up. Because of this, there is an inarguable need to start the print or build on strong platform. The first layer of a 3D print can make or break the project. As the bedrock for which the other layers are laid to […]

Top Benefits From Rapid Prototyping Services

Rapid prototyping services is a collective term that applies to different manufacturing processes capable of converting CAD models into product prototypes. Included in these prototyping services are urethane casting, stereolithography (SLA), CNC machining and in a new type of injection, molding using quick tools. All of these processes are producing parts in the likeness of […]

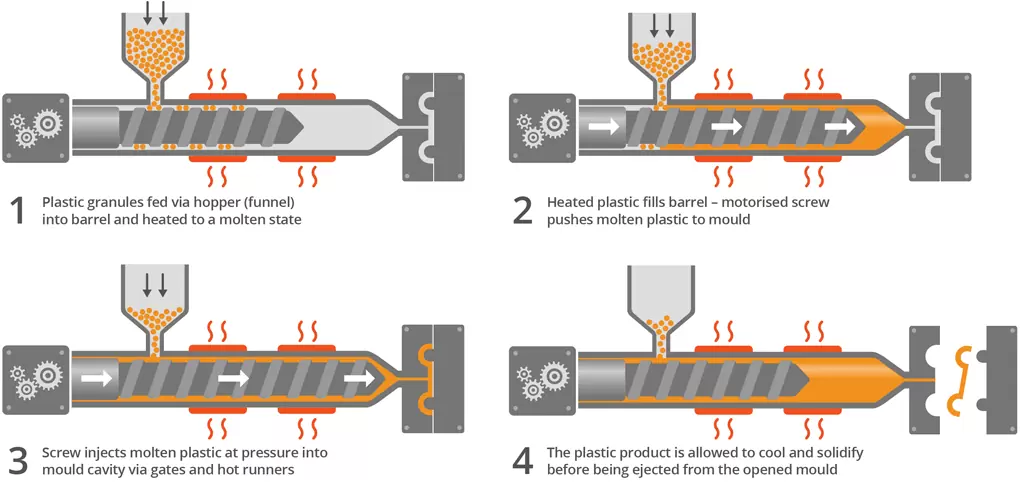

Fill, Pack & Hold – Injection Molding in 3 Steps

Optimizing quality is inarguably the main goal of any injection molding project. This is because part quality impacts a number of metrics that determine the success or failure of that part. Injection molding, in its delicate nature, comprises of 3 steps that can make or break the project. How quality and processing parameters are managed […]

The Importance of Quality Tooling Design on Injection Molded Parts

There is arguably no part more important than the mold tooling of an injection molding project. Not only could your mold tool be the most expensive part of your entire injection molding process, an undetected error in your mold tool will be replicated over the thousands of parts to be made from that tool. The […]