ABOUT US

World-class Digital Machining Factory

With IATF 16949 and ISO 9001 certifications, First Part delivers a wide range of professional services including rapid prototyping, rapid tooling and low volume manufacturing. Our services are diverse and applicable to an extensive number of projects involving a variety of materials.

- Rapid Prototyping Solution

- CNC Prototyping Service

- Rapid Tooling Service

- Rapid Molding Service

- 3D Printing Service

- Vacuum Casting Service

- Sheet Metal Fabrication

- Small Batch Solution

- Surface Finishing Service

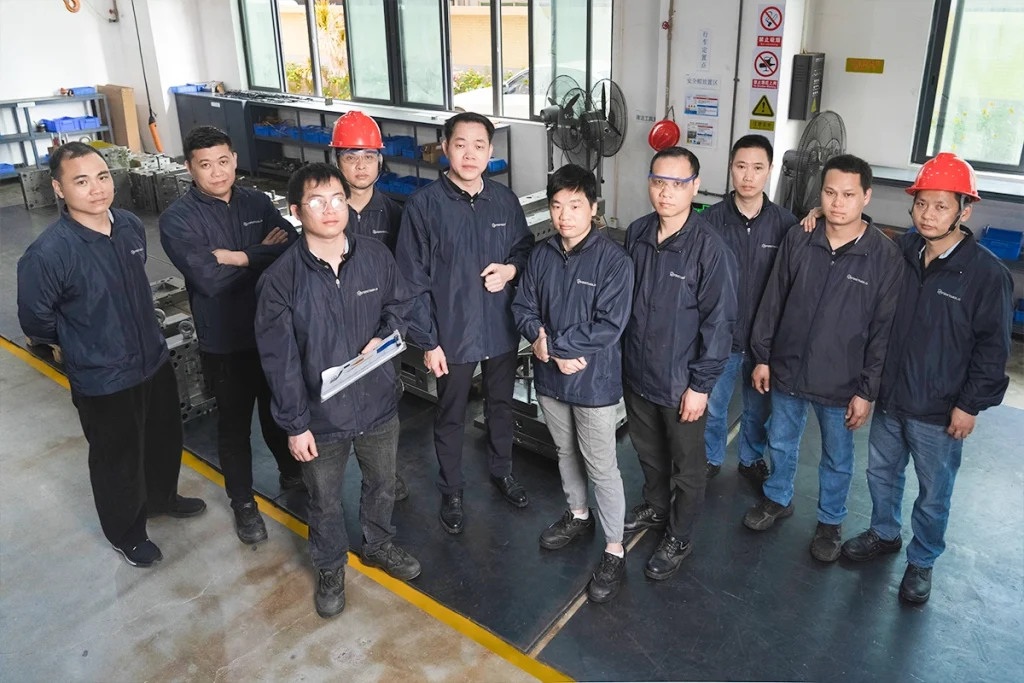

Our Team

Our CNC specialists hold ISO 9001/AS9100 certifications, wielding 5-axis mills for ±0.01mm medical implants and drone motor mounts. With 1500+ mission-critical prototypes delivered, they’ve mastered titanium, PEEK, and Inconel – ask about their NASA-funded lunar rover joint project.

48hr mold turnaround isn’t magic – it’s our AI-driven DFM analysis and veteran toolmakers with 15+ years in automotive tooling. From 100-unit bridge production to multi-cavity molds for IoT startups, we balance cost-efficiency with T0 sample perfection.

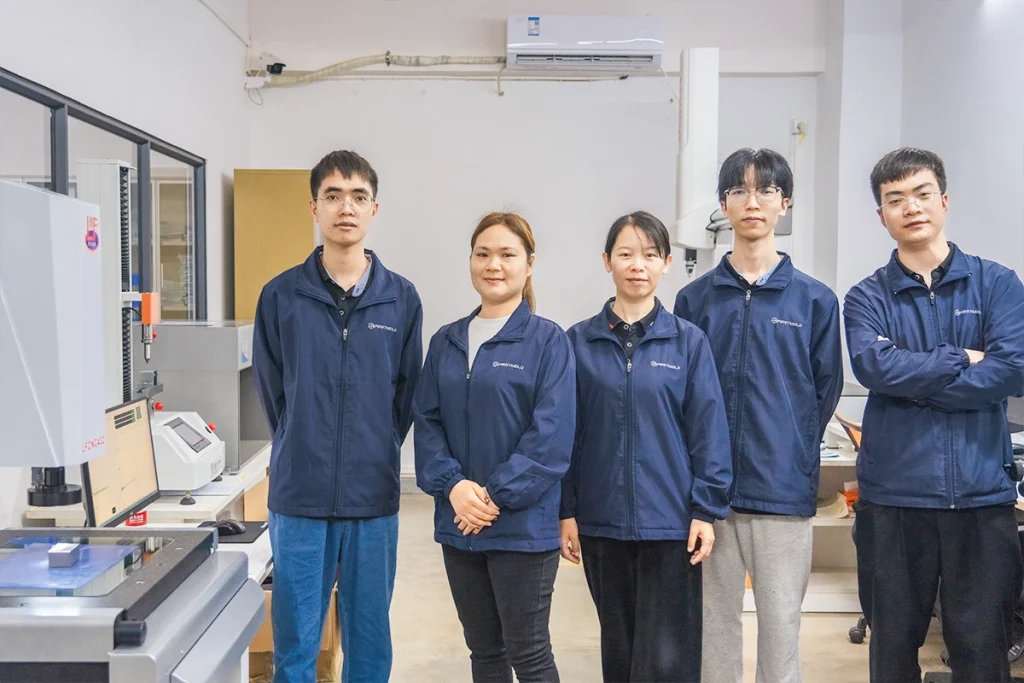

Pharmaceutical-grade cleanrooms meet scientific molding expertise: 0.5% cavity-to-cavity variation control, validated through DOE. They’ve crafted 3M surgical device housings and Y Combinator startups’ first 5k-unit runs – let’s discuss your material matrix (PP/PC/TPU).

Equipped with Zeiss CMMs and CT scanners, this team enforces military-grade standards: 100% dimensional checks, 30% random destructive testing. Their zero-escape policy caught a 0.2mm warp in a Fortune 500 ventilator housing pre-production – saving $2.3M in recalls.

OUR STORY

Follow our journey from inception to excellence, see below our story and learn more about us.

If you have any questions, please do not hesitate to contact us now!

Quick & easy, FREE DFM