You probably can’t tell at first sight, but nearly every single appliance or device you use these days has plastic parts integrated on it. As you begin to learn everything related to the world of Injection Moulding Machine, the main basics of the process are to create a mold of the piece or part you are looking to replicate.

You probably can’t tell at first sight, but nearly every single appliance or device you use these days has plastic parts integrated on it. As you begin to learn everything related to the world of plastic injection molding, the main basics of the process are to create a mold of the piece or part you are looking to replicate.

Creating this mold, even of an existing part is one of the more time-consuming processes out there, mainly because it requires a great deal of patience to recreate or cast the details related to it. Sometimes the process has to be replicated from scratch, as the client requesting the mold does not have the original specs to what he actually needs.

Working your way with everything you have at hand

Creating a mold always begins by doing some reverse-engineering on the component or taking the original prototype and creates a 3D model of it using computer software. This stage of the process can take up to 48 man hours to complete depending on the level of detail required on the part.

When the computer model is finished it has to be referred to the client for revision and approval, is important to keep open channels of communication, since this will happen quite often. After getting the go-ahead from the client is time for some decisions regarding logistics.

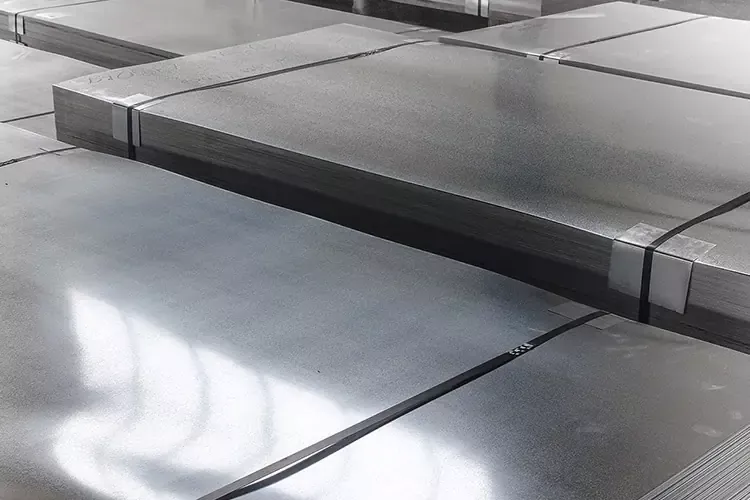

The creative team behind the assignment needs to figure out where the mold cavities should be located as well as working out the measurements to determine the thickness of the steel casts used in the mold.

Attention to detail and engineering

Other considerations have to be figured out as you go to the next step, even figuring out the way the mold will open to release the reproductions. When logistics are taken care of is now the turn of engineering to do their magic and figure out the materials best suited to create the mold.

Most of the time the choice of materials is based on the number of uses the mold is expected to have, as well as the features of the part being created. If we are working a plastic part that requires insulation is very likely that polyethylene will be used, as well as other non-abrasive components.

If you are creating carcasses or plastic parts that will be exposed to the elements, is very likely that engineering will choose to go with fiberglass materials.

Casting the mold and preparing the order

While in the past the mold was created by hand, making this part of the process very expensive, these days such levels of craftsmanship are not required for basic, small plastic components.

By placing the data created for the part in our specialized software we can have specialized hardware create the cast and cut the steel pieces needed to complete the mold. This part of the process can take from 40 to 50 man-hours. After the mold gets inspected and approved by the client, you can start the manufacturing process according to the requests of your order.

A basic shipment of 60 parts measuring 6-inches high and 4-inches wide can take up from 130 to 170 man-hours to complete. There will be a final inspection before dispatching the order, and that will be it.