Designing Snap Fit Components

Designing Snap Fit Components – Common Problems and Solutions Snap-fit components present a quick and easy way of connecting two or more parts together. With the aid of an interlocking “snap and fit” mechanism, designing parts with these components can help you save time, cost and reduce the number of parts in an assembly. In […]

How Rapid Die Casting Produces Parts In A Short Time

Rapid die casting with special tools is a method used by foundries for decades of die-casting prototypes. The advent of stereolithography and computer-aided design modeling has made people interested in the applications provided by this software. You can use secondary machining to add more geometries. The advantage of this method is that it can provide die-cast […]

Top Prototyping Methods When Die Casting

Metal Die-casting is not exactly the first process that comes to mind when product development and prototyping is mentioned. This is because of the versatility and wide availability of options like 3D printing, CNC machining and urethane casting. That being said, metal die-casting solutions can be used in product prototyping across many industries using numerous alloys […]

Working Principle Of Aluminium Die Casting

Advantages of aluminium die castingComplex parts are usually created by making different parts and welding them together, but casting can avoid this situation and enables you to create a part without welding and subsequent post-processing of the joint. — Aluminium die castings have excellent surface finish and precision, which can greatly reduce the amount of processing— […]

7 Common Sheet Metal Welding Problems And How To Fix Them

7 Common Sheet Metal Welding Problems and How to Fix Them Sheet metal parts are coveted for their simplicity, affordability and aesthetically pleasing build from thin plates of metals. The process efficiency, ease of modification, malleability and lightweight also make them ideal for a wide array of applications. Sheet metal fabrication services in china will almost […]

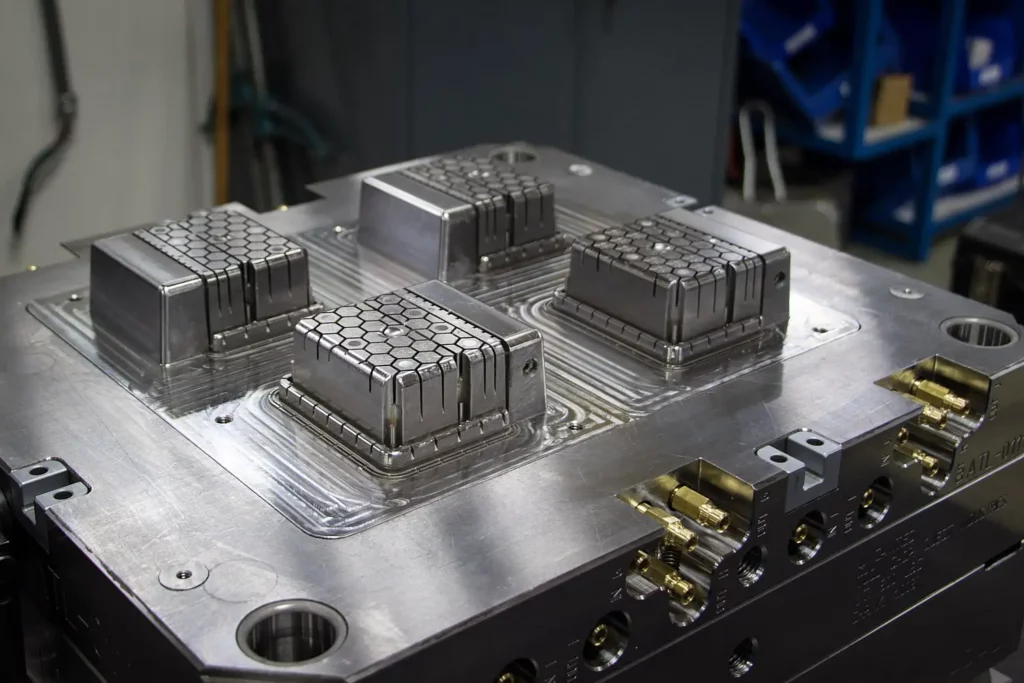

Choosing Between Soft And Hard Tooling Injection Molding

Choosing Between Soft and Hard Tooling Injection Molding Injection molding solutions exist across different production and volume needs. Generally, injection molding tools may be produced via soft or hard tooling. Tooling is the skeletal system of every manufacturing and injection molding operation. It is simply defined as the production of various components and accessories that […]

Workpiece Loading Options For CNC Machining

Workpiece Loading Options for CNC Machining It is almost impossible to highlight the importance of securing a workpiece before commencing any machining work in your workshop. Workpiece loading involves the methods and procedures carried out to load and hold a workpiece during manufacturing. It is all essential process that can help mitigate several risks around […]

Understanding Design For Assembly

Design for Assembly (DFA) Guidelines for Product and Prototype Development Design for assembly (DFA) is the umbrella term for the set of rules that govern part and product design. Design for assembly guidelines work along with design for manufacturing (DFM) rules to ensure that each part is manufactured to specifications, avoid material waste, optimizes machining […]

5 Solid Tips To Help You Create The Ideal BOM

5 Solid Tips to Help You Create the Ideal BOM The Bill of Materials (BOM) refers to a detailed and thorough list of raw materials, quantities required, assemblies, components, sub-assemblies and parts required in the engineering and production of a product. It is a document that gives a comprehensive overview of all the items required […]