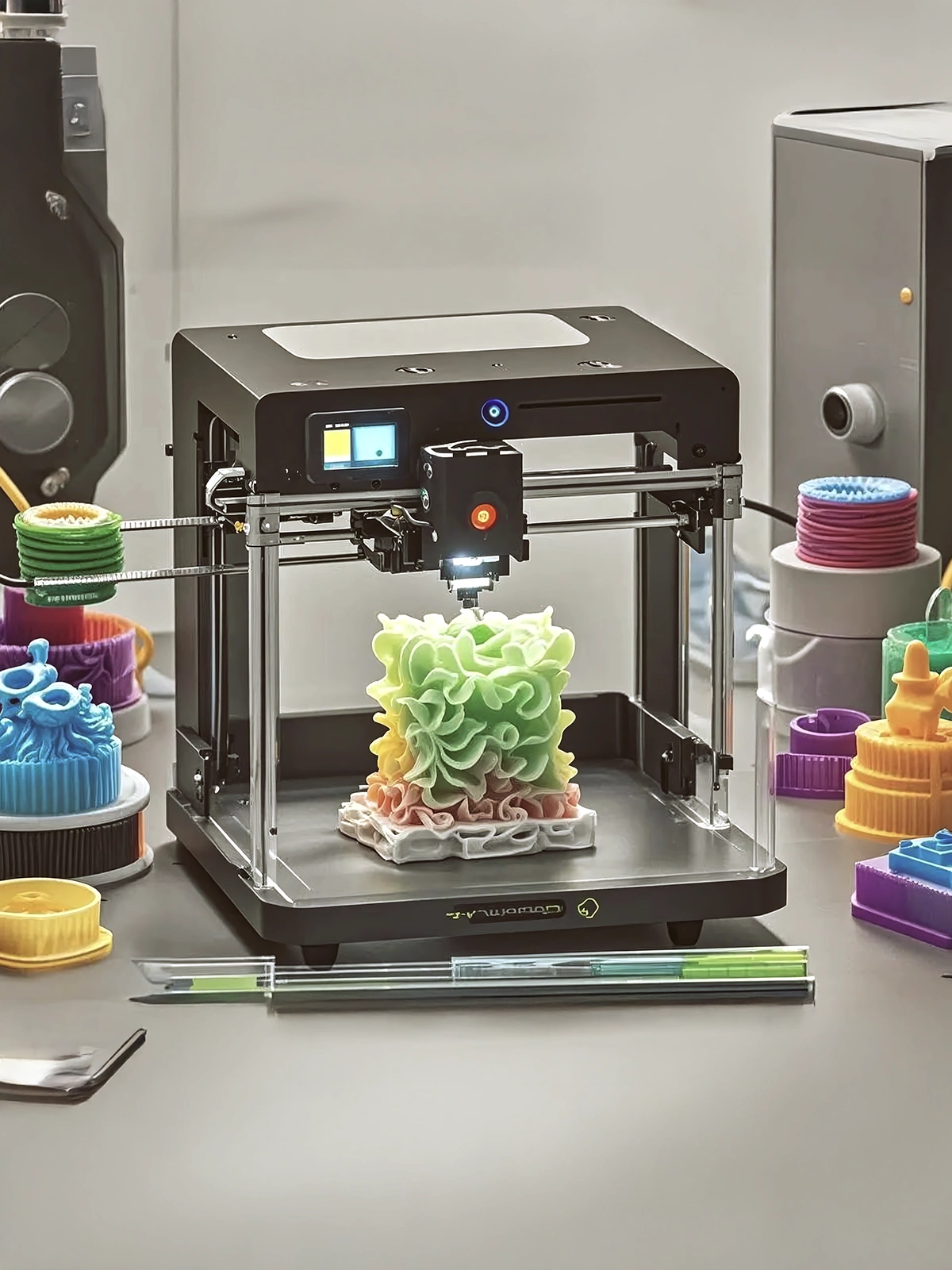

3D PRINTING SERVICES

- ±0.1mm accuracy with industrial-grade printers

- 98% first-pass success rate with AI-supported file analysis

- ISO 9001-certified production facility

Precision-Driven Printing Technologies

At FirstPart, we harness cutting-edge precision-driven technologies to transform complex designs into flawless realities. Our advanced 3D printing systems utilize AI-optimized layering and micron-level resolution, ensuring dimensional accuracy down to ±0.05mm – ideal for aerospace components, medical implants, and automotive prototyping. Unlike conventional methods, our multi-sensor feedback loop dynamically adjusts parameters during printing, eliminating warping and layer misalignment.

| Process | Tolerance | Materials | Best For |

| SLA | ±0.05mm | Resins, Ceramics | Dental models, Jewelry |

| SLM | ±0.1mm | Titanium, Stainless | Aerospace components |

| FDM | ±0.2mm | Nylon, ABS | Functional testing |

SLA

Utilizes ultraviolet lasers to selectively cure liquid photopolymer resin layer-by-layer, achieving ±0.05mm precision for intricate models like jewelry and medical prototypes.

SLM

Employs high-power lasers to fully melt metal powder particles, creating fully dense components (±0.1mm tolerance) for aerospace and medical implants through powder bed fusion.

FDM

Extrudes thermoplastic filaments through heated nozzles, building functional prototypes layer-by-layer (±0.2mm accuracy) using materials like ABS/PLA for cost-effective concept modeling.

200+ Engineering Materials Database

Metal & Alloys

DMLS | Vacuum Debinding & Sintering | Surface roughness Ra ≤6.3μm

Stainless Steel Series

17-4PH: Ideal for hydraulic valve blocks & marine fittings

316L: Prime choice for medical implants

Titanium Alloys

Ti6Al4V: Aerospace structural components

CP-Ti: Bionic trabecular designs for orthopedics (70% porosity)

Aluminum Series

AlSi10Mg: Automotive lightweight parts

Engineering Plastics

Selective Laser Sintering (SLS) | Multi Jet Fusion (MJF) | Tolerance ±0.3%

High-Temperature Plastics

PEEK HP3: Oil drilling seals

PEI (ULTEM 1010): Autoclavable

Wear-Resistant Plastics

PA12 + Carbon Fiber: Metal-replacement bearing bushings

PPA GF50: Automotive fuel system components

Elastomers & Flexible

PolyJet multi-material printing | Liquid Silicone Rubber (LSR) molding

Industrial Elastomers

TPU 95A: Robotic suction cups

EPU 40: Prosthetic cushion layers

Medical-Grade Silicones

MED-4244: Custom respiratory masks

Hyperelastic Resins

Agilus30™: Automotive seal validation prototypes

For applications requiring advanced functionality, we offer carbon fiber composites (45MPa interlayer strength), FDA-certified biodegradable PHBV, and specialty materials like ESD-safe resins (10⁶-10⁹Ω) and optical-grade polymers (92% clarity) – solving challenges in aerospace sustainability, medical disposables, and high-precision electronics.

3D Printing Applications And Gallery

3D printing has revolutionized product development across industries by enabling complex geometries, rapid iteration, and cost-efficient low-volume production. At FirstPart, we specialize in translating these advantages into tangible results

Automotive

3D-printed turbocharger housings (AlSi10Mg), lightweight brake calipers (Scalmalloy®), EV battery cooling plates (Onyx+CF), custom gearshift knobs (Anodized Alumide), headlight reflectors (UV-Resistant PC), exhaust manifolds (Inconel 625), sensor housings (ABS-ESD)

Medical

Patient-specific cranial implants (Ti6Al4V), spinal fusion cages (PEEK), surgical drill guides (Sterile PA12), dental aligners (Biocompatible Resin), porous hip stems (CP-Ti), hearing aid shells (Flexible Photopolymer), orthopedic prosthetics sockets (CarbonPA™), microfluidic lab chips (Clear Resin), biopsy forceps (17-4PH)

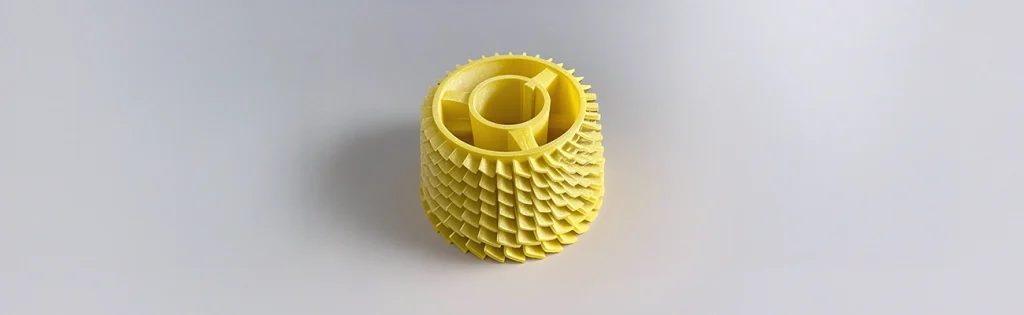

Industrial

Hydraulic pump impellers (Stainless Steel 17-4PH), robotic gripper fingers (PA12 GF50), CNC machine guards (PC-ABS), heat exchanger cores (AlSi7Mg), ESD-safe assembly jigs (ABS-ESD), conveyor belt rollers (Wear-Resistant PA6), injection molding inserts (H13 Tool Steel), pneumatic valve bodies (Nylon 11)

How It Works: 4-Step Ordering

Step 1: Upload & Validate 3D Model

Step 2: Configure Specifications & Pricing

Step 3: Production & Quality Control