Engineered for Automotive Innovation

AUTOMOTIVE PARTS MANUFACTURING

Accelerate your EV, ADAS, and next-gen mobility development with ISO 9001/IATF 16949-certified prototyping – 5-15x faster than traditional methods.

Staying in Top Gear

First part is helping many automakers and automotive product developers to accelerate vehicle design, fine-tune performance, and manufacture future-looking prototypes and production parts to serve a wide array of applications.

As industry developments such as AI driving, hybrid/electric drive trains, and user personalization continue to push the frontier of automotive innovation, Industry-leading vehicle manufacturers are collaborating with First part in seeking ways to improve engine efficiency, reduce weight and ensure scalability. First part continues to be a partner in progress in shortening leadtimes and getting faster market entries.

With the power of advanced multi-axis CNC machining, injection molding, and 3D printing, process engineers and automotive design specialists can mitigate the risk of design failure, lower cost risks, run more interactive testing to make an agile supply chain.

Core Prototyping Processes

5 manufacturing technologies powering automotive innovation

CNC Prototyping

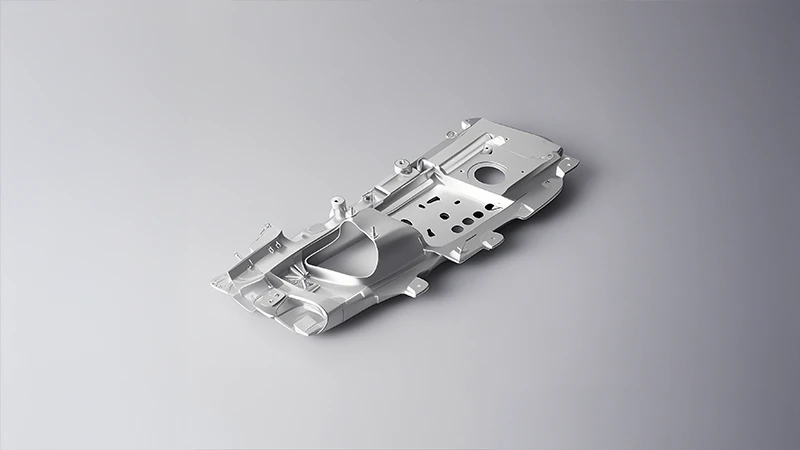

- ±0.02mm tolerance | 50+ metal/alloy options

- Applications: Transmission prototypes, sensor mounts, brake calipers

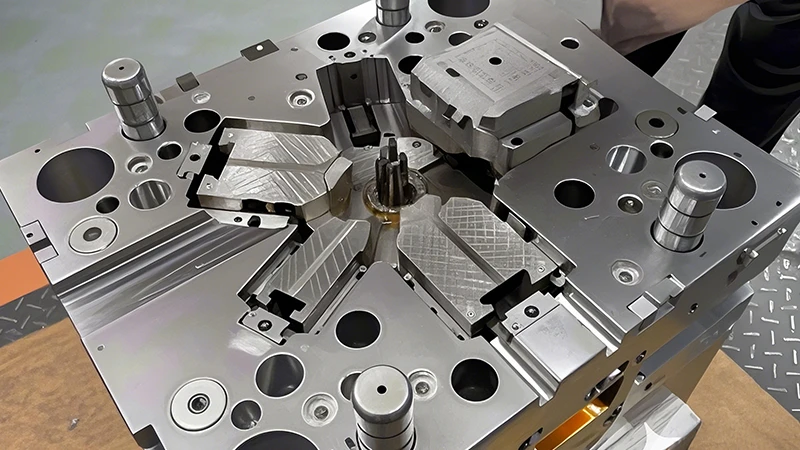

Rapid Tooling

- 300-10k units | Aluminum/steel molds

- Applications: Interior trim, connector housings

Rapid Injection Molding

- <30s cycle time | UL/IMDS-compliant resins

- Applications: Under-hood components, latch systems

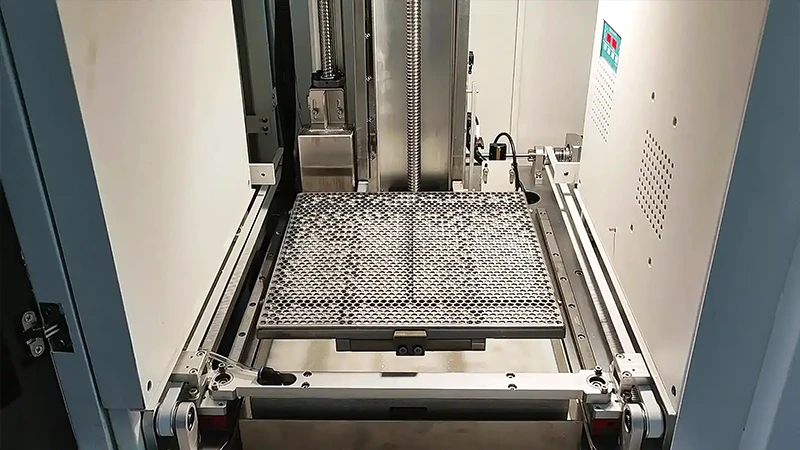

Industrial 3D Printing

- 25% weight reduction typical | 48hr lead time

- Applications: Lightweight brackets, coolant manifolds

Vacuum Casting

- 20+ parts/mold | Shore 30A-80D

- Applications: Seals, dampers, ergonomic controls

Automotive Manufactuing Applications Deep Dive

-

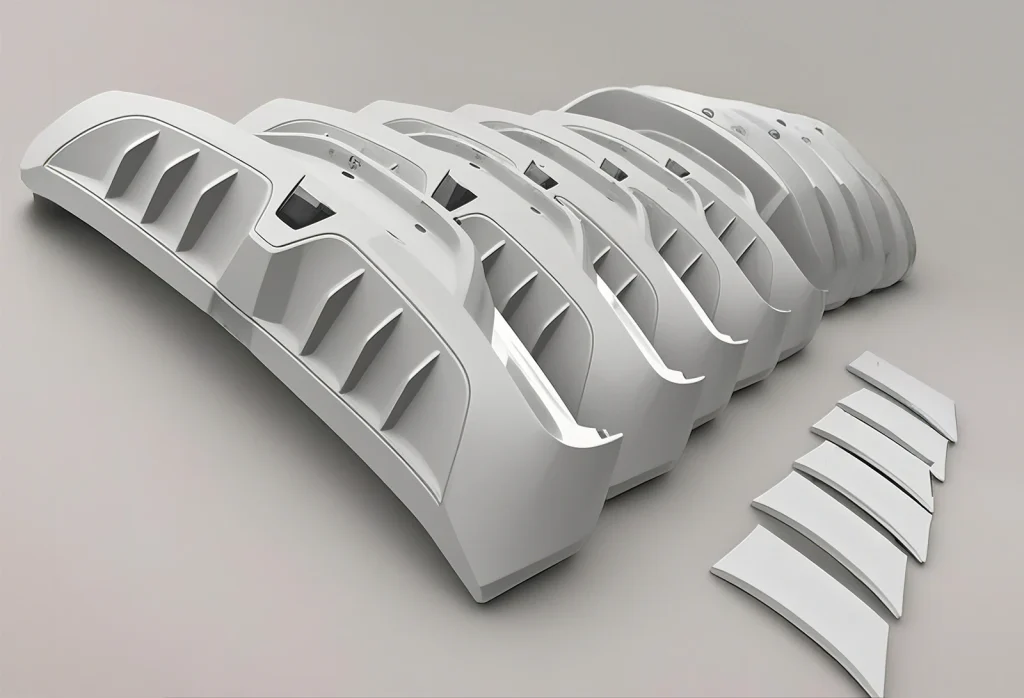

Lighting & Optical ComponentsHeadlight Lenses, Taillight Housings

-

Interior & ErgonomicsDashboard Panels, Center Consoles

-

Structural & Exterior PartsBumpers, Fenders, Spoilers

-

Powertrain & Functional ComponentsEngine Brackets, Intake Manifolds

-

Customization & AftermarketBespoke Accessories, Performance Parts

From Quantum Design to Quantum Leap – Redefining Rapid Prototyping

Get Free Quote

How We Earn Automotive Trust

Crisis-Proof Prototyping

- Day 1, 14:00: Urgent Request

– OEM demands 50x LiDAR brackets in 48hr for crash test - Day 1, 18:30: AI Red Flag

– Thermal simulation predicts 0.3mm warpage at -40°C - Day 1, 21:00: War Room Activated

– CNC team redesigns fixturing + QA pre-cools material batches - Day 3, 10:00: Delivery

– Parts pass 85°C thermal soak test

Why “Industry Standard” Isn’t Our Standard

| Parameter | Our Capability | Industry Average |

| CNC Flatness | ±0.02mm (DIN 876) | ±0.05mm |

| Injection Mold Variation | 0.8% Cavity-to-Cavity | 2.50% |

| 3D Print Isotropic Strength | 98% (ASTM D638) | 85% |

“During our Level 4 autonomous shuttle project, a last-minute design flaw threatened to delay crash testing by 6 weeks. The steering column bracket’s 0.3mm thermal expansion mismatch went undetected until final assembly. FirstPart’s team worked through the night using hybrid prototyping – CNC-machining the core from 6061-T6 aluminum while 3D printing a conformal cooling jacket in ULTEM 9085. Their DFM analysis not only fixed the issue but reduced part mass by 18%. We passed Euro NCAP validation ahead of schedule. Their crisis response? Engineering poetry.”

Dr. Sofia Ivanova

Chief Engineer

“Our hydrogen fuel cell prototype had persistent sealing failures at 700-bar pressures. Traditional vendors blamed ‘material limitations’. FirstPart’s QA team audited our entire process, discovering a 0.1mm radial mismatch between the CNC-machined flange and composite tubing. Using their 5-axis mill with real-time thermal compensation, they reprocessed 316L stainless steel components at ±0.008mm accuracy. But they didn’t stop there – their materials lab formulated a custom ceramic-coated gasket that withstood 50,000 pressure cycles. Now in production for our H2 hypercar line.”

James "Jim" O’Connor

VP of Procurement

Precision Manufacturing at Your Fingertips

How It Works: 4-Step Ordering

Step 1: Upload & Validate 3D Model

Step 2: Configure Specifications & Pricing

Step 3: Production & Quality Control